Quote:

Quote:

On a slant dolly I though the hot went in to the rad at the top and the cooler stuff came out of the bottom.

Yes that is correct.

Ian.

Thanks chaps, ok, I'm going to go for a Revotec one then.

The car runs noticeably quieter with the valve clearances set to factory specs. I wanted to hear what it sounded like factory before I close them up a bit more. I can hear numerous leaks in the front section of the exhaust now and I de feel that this wa the source of my power issues. New one has been ordered though so I'm just waiting for it to arrive.

Bosch coil is on and it runs better already it only needed 1/2 choke to start, so that leads me to believe that I think it needs setting up again now the sparks better, will give her a run and see. Checked the spark and it is noticeably bigger, the leads are new but have some Magnecor leads on the way as well. Thanks Jeroen for that!

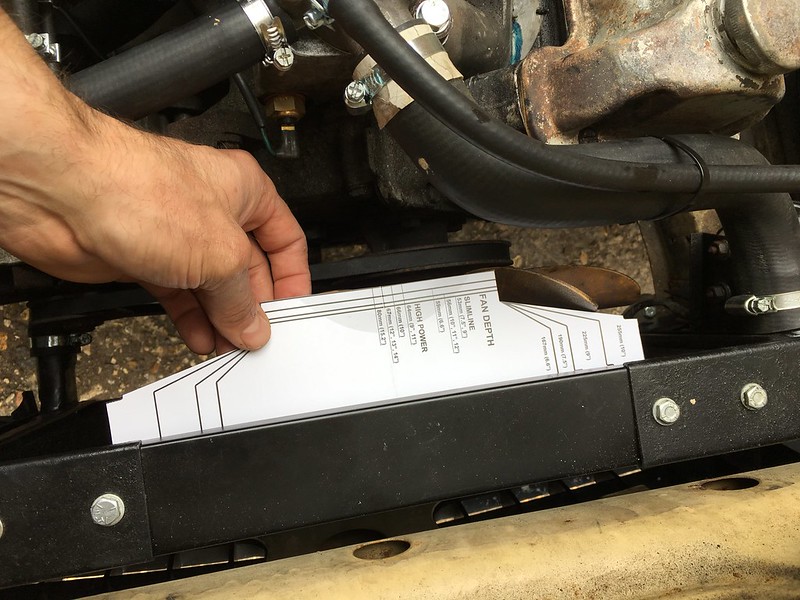

On to fans, I will go with a Revotec one, I know that the cheap £25 ones from eBay are probably fine I just want peace of mind. Size wise, it looks like 11" is the perfect fit and I can fabricate a bracket to mount it to the rad rather than use the through fin mounting things.

a 10" would be a tiny bit too small.

Holes seem to line up with the rad bracket mounts.

In terms of under bonnet clearance the fan pulley will need to be removed to have enough space even for the slimline version I think.