Cheers Mark. Likewise some pukka pics of finished cars helps provide the inspiration to fix the ones needing TLC

Malc; The wing itself was not

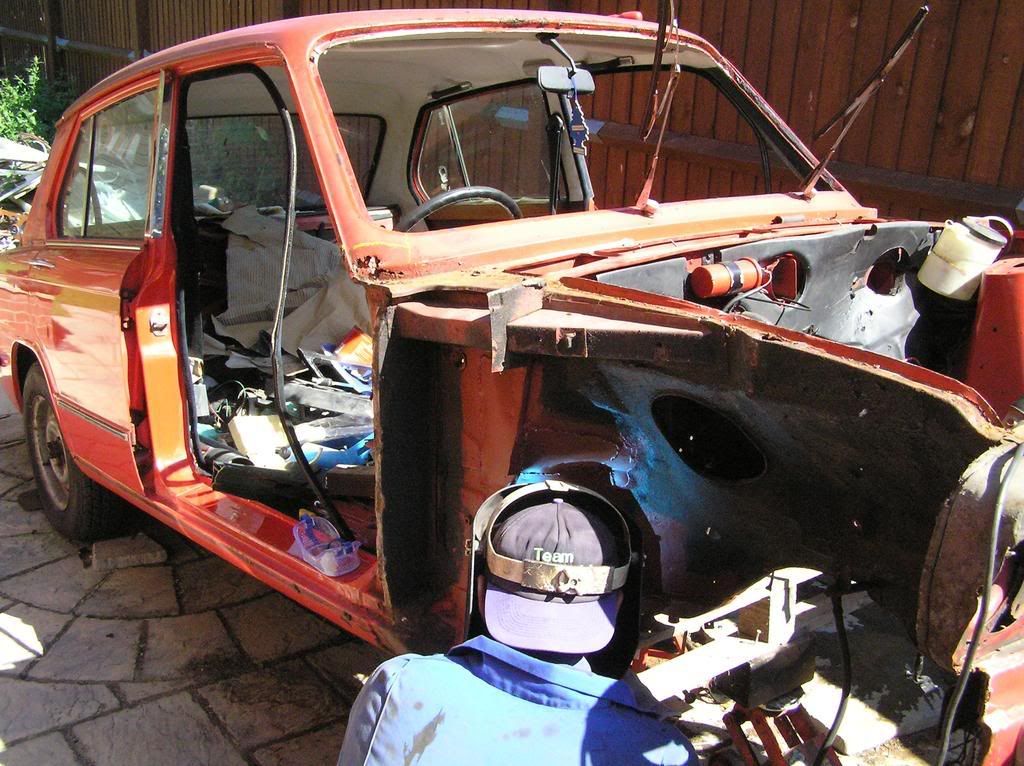

that bad as far as I could see. Although all around the top of the headlamp area was cream crackered. Problem was the inner wing needs attention that can only be done with the wing off. I have the original pic somewhere...

You can see the whole area is filler under the paint. In fact right up to that hairline crack you can see up the wing a bit.

The o/s wing however, is in excellent condition so I tried in vain to get the n/s one off in one bit as practice but failed miserably. I couldn't get it off the curved return by the headlamp. I'm still wondering how to get the o/s one off complete.

My mate with a MIG did the welding on the driveway but was shielded from the wind by some large sheets of ply (old shed roof!!).

Funny thing is, he really isn't happy with the job. Further up there were some blobbby bits of weld which needed a quick grind up before paint.

I however am well chuffed with the job and cant wait to get him over for more of the same

-EDIT: The only real rust on the inner wing is directly behind the arch liner (in front of the A-Post). Not got a clear photo of it but I think you know the area I'm talking about.

Also, the front of the cill (box section bit behind the wing)? Well Alun told me to check that you cant poke a finger up there on the rear hole and the front hole should be half blocked. I remembered to check that bit at purchase time