More just getting it roadworthy and keeping it going.

I bought the car in May 2009, and I've eventually been shamed into posting some pictures here.

I did start, but then Webshots went down, so now the shots are with Flickr.

I started out with good intentions of keeping a detailed log, that didn't last long. Then my camera broke and I had to use a phone camera, excuses excuses.

I can tell from my photo's when bits and pieces were done, so pictures will be added to this thread in time order, using the wonders of the edit buttons.

All comments welcome, my aim is to keep the car going as long as possible within my budget and skills restraints. It often has to make a 65 mile journey north to my brother's garage when I'm stumped, sometimes on the back of a trailer!

I'd rather not do anything that keeps the car off the road for extended periods of time, and where my lock-up garage is situated means I can have electrical power by running an extension cable, but I can't push the car in the garage - it would take at least 5 people to do that, it's like a speed bump at the entrance to garage. The garage is rented, not mine to do with what I will.

Why did I buy this car?

I had a white 1850 when I was 19, bought at 5 years old for £750. It was scrapped 4 years later in 1984 after adding 50,000 miles to the 25,000 purchase mileage.

Then this one appeared on ebay, I bought it for £420 unseen from the Chorley area. A blast from the past. I used to tinker with cars due to cost-saving, but I've never really done much work on them, and never done bodywork. Before buying this, the last time I got my hand hands dirty under a car was probably 1978.......

And so it began..

August 2013

In November 2011 the original engine suddenly became very noisy at the bottom end. This was replaced with an engine I had been told was, "quieter than my Lexus".

It was.

Unfortunately it had a blown head gasket, and after 13 miles of my homeward journey my car was recovered back to Edinburgh, and driven into it's lock-up garage.

The head wouldn't come off.

Pre Xmas 2011 the car was trailered to Dundee, and a third engine fitted.

Yes, this also had a head problem, very annoying as this one had been "worked on".

Unfortunately by a chap who rides a horse swinging a rope to catch cattle.

August 2013 the car barely made the journey to Dundee.

No worries, the head was removed and taken to well known local engineering shop in Dundee. The head is basically scrap. They can fix it, they can fix anything, but I can't afford that,

So... the head from the original engine was dug out, looked at, and the valve guides were seen to move. Off it went to England via courier for the works.

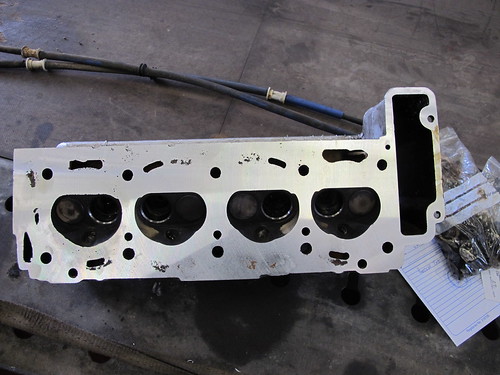

The scrap head:

Block after pressure test and exploratory skim - scrap

Block after pressure test and exploratory skim - scrap by

edindundee, on Flickr

Apparently the holes are previous weld repairs

Apparently the holes are previous weld repairs by

edindundee, on Flickr

Block Prep - can't quite see the marks where the valves had hit #4 piston in a previous life.

The Block

The Block by

edindundee, on Flickr

Head back from the shop:

IMG_2609

IMG_2609 by

edindundee, on Flickr

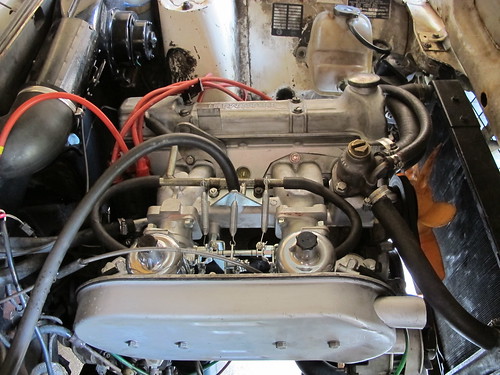

Fitted:

IMG_2637

IMG_2637 by

edindundee, on Flickr

Glad to say there are no leaks on this head, no issues at all, and in 100 miles or so it will receive it's final torque and fill with antifreeze.