Tick tick tick tick nuts.

-

analogue_rogue

Re: Tick tick tick tick nuts.

Without removing it i would check the resistance to the chassis from the starter housing and see if it is high. Then check the gearbox earth to the chassis also. Also the battery earth to chassis. This sounds like a bad earth.

-

MIG Wielder

- TDC Member

- Posts: 2338

- Joined: Sun Mar 16, 2008 2:52 pm

Re: Tick tick tick tick nuts.

Hello All,

I've done a sketch of the electrical side of the Dolomite style pre-engaged starter motor. The reference document is the Sprint workshop manual page 86-24, which has a lot more useful data than the Haynes book.

There are some useful numbers there.

* Pull-in coil resistance = 0.25 to 0.27 ohms

* Hold-in coil resistance = 0.76 to 0.80 ohms.

* Lock current = 463 A , which gives a value for the d.c. resistance of the motor of just 26milli Ohms.

So the solenoid actually has two coils. The pull-in coil to move the solenoid core and operate the heavy duty motor contacts and a much lower current holding-coil to hold the solenoid core in place while the starter motor turns. It takes a lot more force to initially pull the solenoid core in than it does to hold it.

Now Mr Lucas has been very clever and has devised a method of switching off the pull-in coil current when the motor contacts have been made, by returning the pull-in coil current through the motor armature winding. It still works because the pull-in coil resistance is much higher than the motor armature resistance. ( See sketch ). And it saves current drain during the all important starting sequence.

So, you operate the key to start the motor, current flows through the pull-in coil ( 43.5 A ) and also through the hold-in coil ( 15 A ) giving an initial current of 58.5 Amps.

The solenoid core moves forward and the two heavy duty contacts close and apply 12V from the heavy duty battery cable to the starter motor armature. Effectively this switches out the pull-in coil, but don't worry the solenoid core is still held in by the holding coil until the key is released. An extra contact puts 12V on the ignition coil " + " for the ballasted ignition system.

So you can see that we are talking BIG currents here, that need rather specialised equipment to measure.

For instance if we have just 1/2 an ohm of resistance , and 58.5 amps we would drop 29.2 Volts. And we only have 12Volts to start with !

I had a thought; next time the starter goes click-er, click-er, try connecting a jump lead from battery "+ " to the high current link between the starter solenoid and battery. You will get sparks but the motor should turn at high speed as the pull-in coil won't have enough current to pull in. That would at least prove the motor. Actually if you have a really good solenoid, it may actually pull-in and operate, as the two coils now operate in series. Its unlikely though.

So the click sound could be.....

* The pull-in coil operating but not moving far enough to close the heavy duty contacts,

* The holding coil being faulty and not holding the solenoid core in.

* The pull-in coil being faulty, and the solenoid trying to operate with just the hold-in coil.

* The motor armature not turning due to a faulty motor.

* Mechanical obstruction of the starter cog.

Diagnosis by substitution of known good is probably easiest.

Just off to get my anorak dry-cleaned.

HTH,

Cheers All,

Tony.

I've done a sketch of the electrical side of the Dolomite style pre-engaged starter motor. The reference document is the Sprint workshop manual page 86-24, which has a lot more useful data than the Haynes book.

There are some useful numbers there.

* Pull-in coil resistance = 0.25 to 0.27 ohms

* Hold-in coil resistance = 0.76 to 0.80 ohms.

* Lock current = 463 A , which gives a value for the d.c. resistance of the motor of just 26milli Ohms.

So the solenoid actually has two coils. The pull-in coil to move the solenoid core and operate the heavy duty motor contacts and a much lower current holding-coil to hold the solenoid core in place while the starter motor turns. It takes a lot more force to initially pull the solenoid core in than it does to hold it.

Now Mr Lucas has been very clever and has devised a method of switching off the pull-in coil current when the motor contacts have been made, by returning the pull-in coil current through the motor armature winding. It still works because the pull-in coil resistance is much higher than the motor armature resistance. ( See sketch ). And it saves current drain during the all important starting sequence.

So, you operate the key to start the motor, current flows through the pull-in coil ( 43.5 A ) and also through the hold-in coil ( 15 A ) giving an initial current of 58.5 Amps.

The solenoid core moves forward and the two heavy duty contacts close and apply 12V from the heavy duty battery cable to the starter motor armature. Effectively this switches out the pull-in coil, but don't worry the solenoid core is still held in by the holding coil until the key is released. An extra contact puts 12V on the ignition coil " + " for the ballasted ignition system.

So you can see that we are talking BIG currents here, that need rather specialised equipment to measure.

For instance if we have just 1/2 an ohm of resistance , and 58.5 amps we would drop 29.2 Volts. And we only have 12Volts to start with !

I had a thought; next time the starter goes click-er, click-er, try connecting a jump lead from battery "+ " to the high current link between the starter solenoid and battery. You will get sparks but the motor should turn at high speed as the pull-in coil won't have enough current to pull in. That would at least prove the motor. Actually if you have a really good solenoid, it may actually pull-in and operate, as the two coils now operate in series. Its unlikely though.

So the click sound could be.....

* The pull-in coil operating but not moving far enough to close the heavy duty contacts,

* The holding coil being faulty and not holding the solenoid core in.

* The pull-in coil being faulty, and the solenoid trying to operate with just the hold-in coil.

* The motor armature not turning due to a faulty motor.

* Mechanical obstruction of the starter cog.

Diagnosis by substitution of known good is probably easiest.

Just off to get my anorak dry-cleaned.

HTH,

Cheers All,

Tony.

Last edited by MIG Wielder on Tue Dec 04, 2012 9:39 pm, edited 1 time in total.

-

Richard the old one

- TDC Member

- Posts: 1219

- Joined: Thu Sep 28, 2006 10:06 pm

- Location: Bristol

Re: Tick tick tick tick nuts.

It would certainly be nice to get to the bottom of the problem where the starter does not operate or turns the engine over slowly as I have also had this problem in the past and the only way I have got around the problem has been by replacing the starter. Hence I believe the problem must be in the starter or its associatedd solenoid. I have even taken some of the solenoids apart to check on the contacts only to find that this has not been the problem. I also suspected that one or more of the brushes might not be making contact with the armature but again have not found any signs of this. I have stripped a number of the starters with the problem. The only thing that I have not checked is the actual armatures so I do wonder if they are the cause of the problem.

I have a 1977 official 1500hl repair operations manual and that gives slightly different values for the pull in winding 0.21 to 0.25 ohms and the Hold in as being 0.90 to 1.10 ohms to those that Tony has found in the Sprint manual. It also shows that the motor field windings are in series with the armature and not in parallel as shown in Tony's diagram.

I have a 1977 official 1500hl repair operations manual and that gives slightly different values for the pull in winding 0.21 to 0.25 ohms and the Hold in as being 0.90 to 1.10 ohms to those that Tony has found in the Sprint manual. It also shows that the motor field windings are in series with the armature and not in parallel as shown in Tony's diagram.

Re: Tick tick tick tick nuts.

Excellent post Tony =D> I've a 1500HL factory manual too, I'll see what edition & figures my copy gives. I've also got a few company toys lying around at home that should help shed some more light now I have figures to work to

1978 Pageant Sprint - the rustomite, 1972 Spitfire IV - sprintfire project, 1968 Valencia GT6 II - little Blue, 1980 Vermillion 1500HL - resting. 1974 Sienna 1500TC, Mrs Weevils big brown.

-

Jon Tilson

- Guest contributor

- Posts: 11179

- Joined: Tue Oct 03, 2006 9:45 pm

- Location: Middlesex

Re: Tick tick tick tick nuts.

Well you learn something new every day...I now know that the solenoids for starterts have 2 coils like the overdrive ones....

Makes perfect sense, but I'd never thought about it before...

Tony's post is worthy of the Wiki when we have the additional numbers for the slant starters added....

nice...

Jonners

Makes perfect sense, but I'd never thought about it before...

Tony's post is worthy of the Wiki when we have the additional numbers for the slant starters added....

nice...

Jonners

Note from Admin: sadly Jon passed away in February 2018 but his humour and wealth of knowledge will be fondly remembered by all. RIP Jonners.

- xvivalve

- TDC West Mids Area Organiser

- Posts: 13592

- Joined: Thu Sep 28, 2006 1:13 pm

- Location: Over here...can't you see me?

Re: Tick tick tick tick nuts.

Interestingly Julian, the starter that your car is currently wearing was once the property of Richard Old! It may be the same problem he experienced, transfered!

(It was fully reconditioned and tested between times)

(It was fully reconditioned and tested between times)

-

MIG Wielder

- TDC Member

- Posts: 2338

- Joined: Sun Mar 16, 2008 2:52 pm

Re: Tick tick tick tick nuts.

Thanks Richard, Yes you are quite correct. I now remember from my electrical lectures that series wound d.c. motors have maximum torque at zero rpm ( just what we need for Dolomite starters) rather than shunt wound motors.

I've edited the .png to reflect that.

Cheers All,

Tony.

I've edited the .png to reflect that.

Cheers All,

Tony.

Re: Tick tick tick tick nuts.

Progress.

First up I must say credit to Kwik-Fit in Bracknell for pointing out the problem.

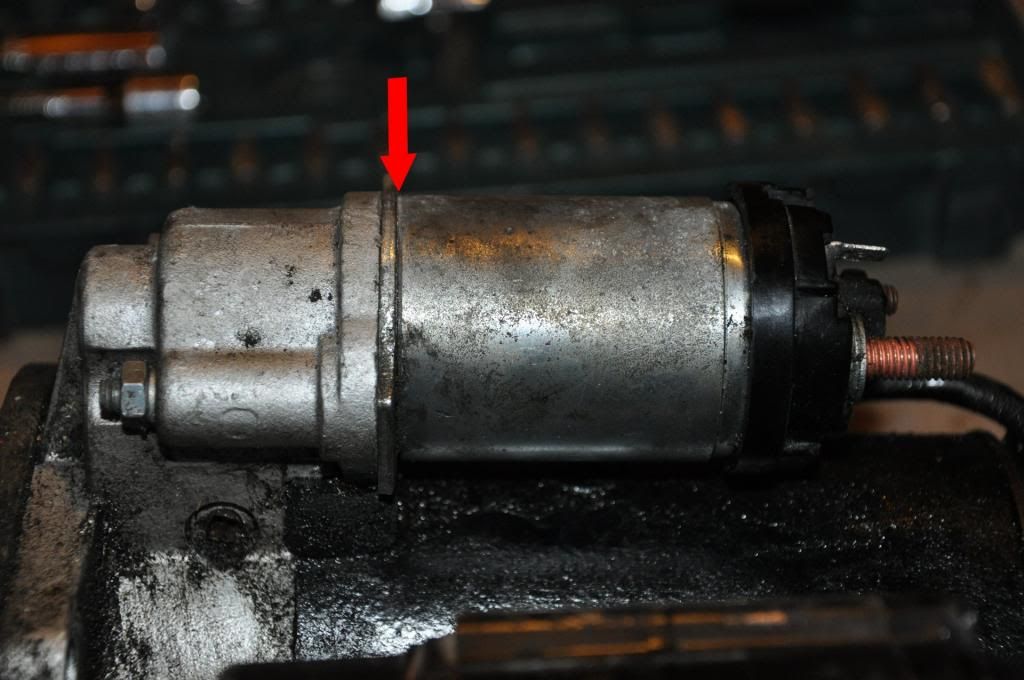

The solenoid body was loose at the marked joint, I kept quiet Monday as I wanted to be sure it's supposed to be tight at that point.

Upon taking the solenoid off it is clear that it should be. Both the screws (of which I've removed one in this photo) needed about a turn to be tight.

On removal of the screws thread lock residue was visible so replaced them with some fresh.

Next I tried checking the solenoid resistances but I couldn't get good readings. I'm using a Fluke 87 by the way not a £15 Maplin special that lives in the garage. It really needs a milliohm meter down that far so that can go on the company shopping list.

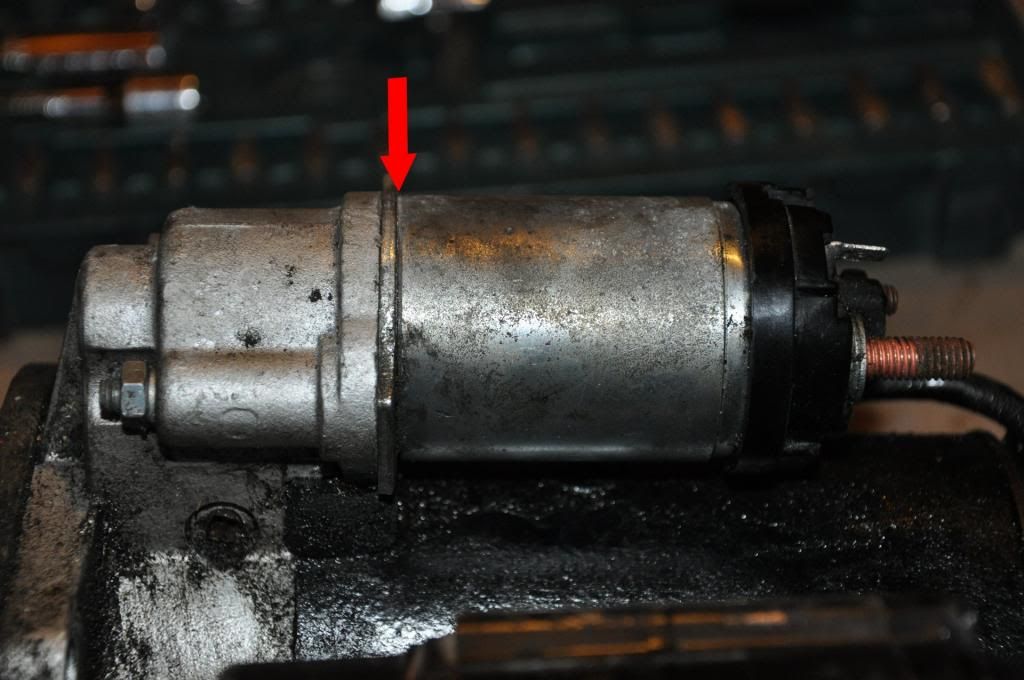

Here's the two solenoid types for comparison:

So having tightened it all up I refitted it to the car and turned the key. First two tries it went fine then I got a click so I decided I'd do 20 & count, on the 7th the engine turned over audibly much faster so I started counting those too:

3 Click

8 Fast

9 Slow & sluggish.

Battery is on charge now, I'll repeat the test in the morning then swap for the motor with the OE solenoid and see what I get with that.

First up I must say credit to Kwik-Fit in Bracknell for pointing out the problem.

The solenoid body was loose at the marked joint, I kept quiet Monday as I wanted to be sure it's supposed to be tight at that point.

Upon taking the solenoid off it is clear that it should be. Both the screws (of which I've removed one in this photo) needed about a turn to be tight.

On removal of the screws thread lock residue was visible so replaced them with some fresh.

Next I tried checking the solenoid resistances but I couldn't get good readings. I'm using a Fluke 87 by the way not a £15 Maplin special that lives in the garage. It really needs a milliohm meter down that far so that can go on the company shopping list.

Here's the two solenoid types for comparison:

So having tightened it all up I refitted it to the car and turned the key. First two tries it went fine then I got a click so I decided I'd do 20 & count, on the 7th the engine turned over audibly much faster so I started counting those too:

3 Click

8 Fast

9 Slow & sluggish.

Battery is on charge now, I'll repeat the test in the morning then swap for the motor with the OE solenoid and see what I get with that.

1978 Pageant Sprint - the rustomite, 1972 Spitfire IV - sprintfire project, 1968 Valencia GT6 II - little Blue, 1980 Vermillion 1500HL - resting. 1974 Sienna 1500TC, Mrs Weevils big brown.

-

analogue_rogue

Re: Tick tick tick tick nuts.

This still sounds like a bad earth. Whether down o poor contact in the starter itself or the eartg back to the battery from the starter. I would the entire path back carefully. I have had many cars over the years with the same symptoms and most were simply corroded earth cables. Mainly gearbox to chassis but clearly it could be anywhere.

-

Richard the old one

- TDC Member

- Posts: 1219

- Joined: Thu Sep 28, 2006 10:06 pm

- Location: Bristol

Re: Tick tick tick tick nuts.

Tinweevil keep up the good work. It would be nice to get to the bottom of this common problem.

I accept that sometimes the slow turning over will be caused by poor connections causing voltage drops but so many people have checked all the connections and found no problems that there must be something else. I have stripped and cleaned the contacts in a number of solenoids but they were not the source of the problem. Most owners resort to changing the starter motor incl solenoid and the problem is then solved so it seems to indicate the problem is within the starter / solenoid.

When the starter just clicks I do wonder if the armature has stopped in a bad section. When I was an electrical fitter apprentice I was taught how to do a basic test on an armature but the exact details of how to do it are long gone and I do not have the necessary equipment. I know that the workshop manual does not indicate the need to undercut the insulation between the armature segments but I might give it a try at some point however I have not noticed any problem with the insulation not wearing at the same rate as the copper.

I accept that sometimes the slow turning over will be caused by poor connections causing voltage drops but so many people have checked all the connections and found no problems that there must be something else. I have stripped and cleaned the contacts in a number of solenoids but they were not the source of the problem. Most owners resort to changing the starter motor incl solenoid and the problem is then solved so it seems to indicate the problem is within the starter / solenoid.

When the starter just clicks I do wonder if the armature has stopped in a bad section. When I was an electrical fitter apprentice I was taught how to do a basic test on an armature but the exact details of how to do it are long gone and I do not have the necessary equipment. I know that the workshop manual does not indicate the need to undercut the insulation between the armature segments but I might give it a try at some point however I have not noticed any problem with the insulation not wearing at the same rate as the copper.

Re: Tick tick tick tick nuts.

Commutator

Vindicator Sprint, Honda Fireblade RRX 919cc, re-powered by AB Performance. Quick.

-

analogue_rogue

Re: Tick tick tick tick nuts.

Have you used a serviceable spare to confirmthe fault is in the starter?

Just because others have problems with the starter itself doesnt mean thats what it is this time. Check te nasics. Measure the resistance from the starter tothe battery if its more than about 3 ohms i would suggest there is a poor earth. If it is less than 3 ohms inwould agree the problem is in the starter or supply to the starter.

Just because others have problems with the starter itself doesnt mean thats what it is this time. Check te nasics. Measure the resistance from the starter tothe battery if its more than about 3 ohms i would suggest there is a poor earth. If it is less than 3 ohms inwould agree the problem is in the starter or supply to the starter.

Re: Tick tick tick tick nuts.

Thanks Richard, will do. I would like to prove the alternative solenoid as viable as if they aren't and original ones are becoming a scarce we have a problem.

Right then. 2-3 seconds cranking each time using the Fluke 87 with Min/Max capture as appropriate. I'm checking every link to prove/disprove the bad earth bad connection theory. Readings numbered to make conversation easier later. Slow or fast noted below relates to cranking speed and is not overly scientific but some of the tests suggest it's not entirely subjective.

Test 1. V battery

1.1. 10.38 - slow

1.2. 10.22 - slow

1.3. 10.19 - slow

Test 2. V return (Starter fixing bolt to battery -ve)

2.1. 0.144 - slow

2.2. 0.142 - slow

2.3. 0.144 - slow

Test 3. Battery V+ to solenoid+ (This link uses a shortened Sprint/1850 cable that has the 4 way tapoff in it)

3.1. 0.109 - fast

3.2. 0.109 - slow

3.3. 0.106 - fast

Test 4. Solenoid+ to motor+ (IE across the solenoid contacts and the link wire)

4.1. 10.73 - click

4.2. 0.53 - slow

4.3. 0.78 - slow

Test 5. Battery V+ to solenoid WR (This is via a relay instead of the OE route through the ignition switch, see photo below)

5.1. 0.15 - fast

5.2. 0.17 - slow

5.3. 0.14 - fast

Test 6. Battery V+ to solenoid WR with relay modification removed (As BL intended, current path via the ignition switch)

6.1. 3.62 - click

6.2. 3.52 - click

6.3. 1.57 - slow

Test 7. Solenoid current. (using the max function on the meter means these readings relate to the pull in coil. Current clamp is an Iso-Tech ICA37N on 100A scale)

7.1.

7.2. Results discarded as I am unsure I had the current probe correctly oriented.

7.3.

Test 8. Motor current. (Yes, I did remember to put the clamp below the 4 way tapoff. Current clamp on 600A scale)

8.1. 210A fast

8.2. 258A slow

8.3. 254A slow

Test 9. Solenoid current. (Repeat of test 7)

9.1. 55A slow

9.2. 24A fast

9.3. 41A slow

Test 10. V battery again as test 1 to see how flat it is now.

10.1. 9.07 slow

Yup, flat.

I don't see anything untoward in tests 1-3. Battery voltage during cranking is where this thread started so I can't call the test 1 figures bad or good, maybe by the end of this we'll know. Test 4 is where it gets interesting. Clearly in test 4.1 the solenoid contacts have not closed. I'll not speculate on why yet.

Test 5 shows very low voltage drop in the solenoid current path using the modified wiring.

You can see in the above the current carrying path for the solenoid through the modified Sprint cable on the left (battery terminal is the out of focus blob at the left of shot), 4 way connector, brown wire, relay & red wire. 18" maybe rather than the several yards via the column.

Test 6 is where things start to get interesting. I did this test just to see what improvement there was and revealed rather more. The very large voltage drop in tests 6.1 & 6.2 could simply be that the ignition switch contacts are dirty having been relieved of their high current duties for so long. It struck me as rather interesting though that the symptoms with this clear fault match the symptoms we are looking for. And match it did, the click was just the same as the others I've heard. 6.3 gives us a real clue what improvement the relay and shorter current carrying path gives. A very significant one.

It was as I was about to do test 7 and started to think about currents I had something of a eurika-oh-s##t moment. The solenoid pull in resistance Richard posted above means that the pull in current, assuming 12.6 volts at the battery, is up to 60A for a standard solenoid. For this solenoid we don't have figures. 60A is much higher than I realised when I fitted the relay, could that be the problem? Well the relay is rated for 30A continuous. It will carry more but get hot and self destruct eventually. The test 9 results show that indeed it can carry >30A. Is there anything in the fact that when the solenoid current was lowest I got fast cranking? I don't know but doubt it, more testing would be needed to investigate that. I do think just for belt & braces I will change to a 70A relay and thicken up the solenoid path cables.

Test 8 confirms a few things. The current is lowest when cranking fast as we would expect for this motor type. The battery is good, it is delivering close to it's CCA rating to the motor on top of whatever is going to everything else that's live during cranking. Most of that CCA is getting used even when it cranks fast and even a healthy battery can be the limiting factor very easily. It really is a nuisance that the higher capacity 015 type is no longer available.

Next I shall fit the OE motor.

Late addition: Taking the average Vreturn and average Imotor from above the resistance in the engine 0V connection is in the milliohm range.

[Edit] Battery is a Yuasa 038, 265 CCA

Right then. 2-3 seconds cranking each time using the Fluke 87 with Min/Max capture as appropriate. I'm checking every link to prove/disprove the bad earth bad connection theory. Readings numbered to make conversation easier later. Slow or fast noted below relates to cranking speed and is not overly scientific but some of the tests suggest it's not entirely subjective.

Test 1. V battery

1.1. 10.38 - slow

1.2. 10.22 - slow

1.3. 10.19 - slow

Test 2. V return (Starter fixing bolt to battery -ve)

2.1. 0.144 - slow

2.2. 0.142 - slow

2.3. 0.144 - slow

Test 3. Battery V+ to solenoid+ (This link uses a shortened Sprint/1850 cable that has the 4 way tapoff in it)

3.1. 0.109 - fast

3.2. 0.109 - slow

3.3. 0.106 - fast

Test 4. Solenoid+ to motor+ (IE across the solenoid contacts and the link wire)

4.1. 10.73 - click

4.2. 0.53 - slow

4.3. 0.78 - slow

Test 5. Battery V+ to solenoid WR (This is via a relay instead of the OE route through the ignition switch, see photo below)

5.1. 0.15 - fast

5.2. 0.17 - slow

5.3. 0.14 - fast

Test 6. Battery V+ to solenoid WR with relay modification removed (As BL intended, current path via the ignition switch)

6.1. 3.62 - click

6.2. 3.52 - click

6.3. 1.57 - slow

Test 7. Solenoid current. (using the max function on the meter means these readings relate to the pull in coil. Current clamp is an Iso-Tech ICA37N on 100A scale)

7.1.

7.2. Results discarded as I am unsure I had the current probe correctly oriented.

7.3.

Test 8. Motor current. (Yes, I did remember to put the clamp below the 4 way tapoff. Current clamp on 600A scale)

8.1. 210A fast

8.2. 258A slow

8.3. 254A slow

Test 9. Solenoid current. (Repeat of test 7)

9.1. 55A slow

9.2. 24A fast

9.3. 41A slow

Test 10. V battery again as test 1 to see how flat it is now.

10.1. 9.07 slow

Yup, flat.

I don't see anything untoward in tests 1-3. Battery voltage during cranking is where this thread started so I can't call the test 1 figures bad or good, maybe by the end of this we'll know. Test 4 is where it gets interesting. Clearly in test 4.1 the solenoid contacts have not closed. I'll not speculate on why yet.

Test 5 shows very low voltage drop in the solenoid current path using the modified wiring.

You can see in the above the current carrying path for the solenoid through the modified Sprint cable on the left (battery terminal is the out of focus blob at the left of shot), 4 way connector, brown wire, relay & red wire. 18" maybe rather than the several yards via the column.

Test 6 is where things start to get interesting. I did this test just to see what improvement there was and revealed rather more. The very large voltage drop in tests 6.1 & 6.2 could simply be that the ignition switch contacts are dirty having been relieved of their high current duties for so long. It struck me as rather interesting though that the symptoms with this clear fault match the symptoms we are looking for. And match it did, the click was just the same as the others I've heard. 6.3 gives us a real clue what improvement the relay and shorter current carrying path gives. A very significant one.

It was as I was about to do test 7 and started to think about currents I had something of a eurika-oh-s##t moment. The solenoid pull in resistance Richard posted above means that the pull in current, assuming 12.6 volts at the battery, is up to 60A for a standard solenoid. For this solenoid we don't have figures. 60A is much higher than I realised when I fitted the relay, could that be the problem? Well the relay is rated for 30A continuous. It will carry more but get hot and self destruct eventually. The test 9 results show that indeed it can carry >30A. Is there anything in the fact that when the solenoid current was lowest I got fast cranking? I don't know but doubt it, more testing would be needed to investigate that. I do think just for belt & braces I will change to a 70A relay and thicken up the solenoid path cables.

Test 8 confirms a few things. The current is lowest when cranking fast as we would expect for this motor type. The battery is good, it is delivering close to it's CCA rating to the motor on top of whatever is going to everything else that's live during cranking. Most of that CCA is getting used even when it cranks fast and even a healthy battery can be the limiting factor very easily. It really is a nuisance that the higher capacity 015 type is no longer available.

Next I shall fit the OE motor.

Late addition: Taking the average Vreturn and average Imotor from above the resistance in the engine 0V connection is in the milliohm range.

[Edit] Battery is a Yuasa 038, 265 CCA

Last edited by tinweevil on Sun Dec 09, 2012 2:21 pm, edited 1 time in total.

1978 Pageant Sprint - the rustomite, 1972 Spitfire IV - sprintfire project, 1968 Valencia GT6 II - little Blue, 1980 Vermillion 1500HL - resting. 1974 Sienna 1500TC, Mrs Weevils big brown.

-

analogue_rogue

Re: Tick tick tick tick nuts.

Thats some heavy testing lol!! But rather than guessing the resistances itnwouldntake two ticks (excuse the pun) to measure the resistance?? Edited because i cant spell for toffee!!!

Re: Tick tick tick tick nuts.

Oh go on then.analogue_rogue wrote:Thats some heavy testing lol!! But rather than guessing the resistances itnwouldntake two ticks (excuse the pun) to measure the resistance?? Edited because i cant spell for toffee!!!

Starter bolt to battery -ve clamp - 0.2Ω

Battery +ve clamp to solenoid +ve - 0.2Ω

Battery +ve clamp to relay - 0.2Ω

Relay to solenoid WR - 0.2Ω

Hmm bit of a pattern there

Meter leads directly connected - 0.2Ω

Which means to the accuracy of a Fluke 87 all the above connections are zero resistance.

New motor on. Every test listed below the engine cranked in a fast and spritely fashion. No clicks and no sluggish turnover.

Test 11. V battery.

11.1. 10.95

11.2. 10.61

11.3. 10.54

Test 12. Return current. Using the current clamp on the engine earth lead. This measures the combined motor and solenoid current.

12.1. 192A

12.2. 204A

12.3. 196A

Test 13. Motor current. As test 8.

13.1. 198A

13.2. 194A

13.3. 195A

Test 14. Solenoid current. As tests 7&9.

14.1 38A

14.2 37A

14.3 35A

I've not repeated any of the other tests because this is looking like a problem that is beyond my motor theory knowledge. The motor current is around the same as in test 8.1 every time and the battery is comfortably clear of max CCA. So why was the old motor sometimes taking more? The load isn't changing from test to test. I can argue it either way to point the finger at the solenoid or the motor which is why I say it's beyond my knowledge. I've given the battery a royal hammering already this weekend so unless anyone would like anything repeated or tested differently that's it for now. My immediate problem is solved but where does that leave other 1500 owners and the club? Any hypothesis as to what is going on? On the plus side it looks I can answer my original question.

A freshly charged and healthy battery should have a cranking voltage of around 10.5 but anything above 9 should start the car.

I'd like to get another example of each solenoid type and move things about a bit. What would the new style solenoid with the 'good' motor reveal? Good is in quotes because there's no proof positive that the motor now on my bench is bad. The new style solenoid has several advantages

- It's available still.

- It is smaller & lighter.

- The +ve terminal is longer giving room for better quality ring crimps than the OE ones.

- The +ve terminal is also fatter so you're less nervous about stripping the thread and there is more good contact area.

I need to discuss this with Alun before I can decide how to progress the investigation. However, if anyone has any 1500 starter motors that are old core and waiting to go to Alun for reconditioning could they please be routed via me? I may be able to learn more that way and can drop them off to Alun when done.

1978 Pageant Sprint - the rustomite, 1972 Spitfire IV - sprintfire project, 1968 Valencia GT6 II - little Blue, 1980 Vermillion 1500HL - resting. 1974 Sienna 1500TC, Mrs Weevils big brown.