Page 1 of 1

Info on Sprint Cam

Posted: Fri Feb 03, 2012 9:25 am

by Stevecox

Hi All

Looking for any Information on a Spare Cam I have , which I hope to use in a Sprint motor Im

Having rebuilt.

All Stampings along the shaft are the same as a standard Stanpart cam , and on the Sprocket

Flange it's Stamped ( CE 1 C 944 )

Thanks in advance

Steve

Re: Info on Sprint Cam

Posted: Fri Feb 03, 2012 1:32 pm

by Mad Mart

Steve

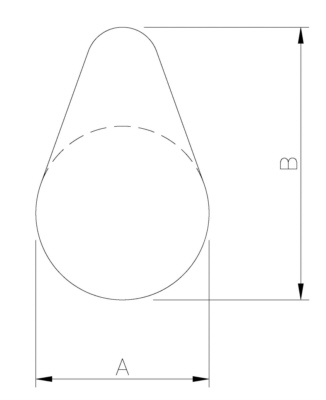

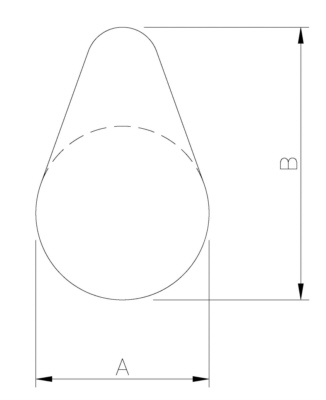

Look on the end of the camshaft nearest the windscreen & see what is stamped on there. Also, if you measure the lobe...

...and subtract A from B, this will give the total lift of the cam, which will be an indication of which cam it is.

Re: Info on Sprint Cam

Posted: Sat Feb 04, 2012 1:37 am

by Stevecox

Thanks Mart

Will have a look Monday , when I'm back at work.

Steve

Re: Info on Sprint Cam

Posted: Mon Feb 06, 2012 12:03 pm

by Stevecox

Hi All

Stamping on the back end of the Cam is ( ZHW 5 )

A = 30.1 mm

B = 40.45 mm

Lift = 10.35 mm

The measurements are for the Cam on the Left

Any Info much appreciated

Cheers

Steve

Re: Info on Sprint Cam

Posted: Mon Feb 06, 2012 1:14 pm

by Mad Mart

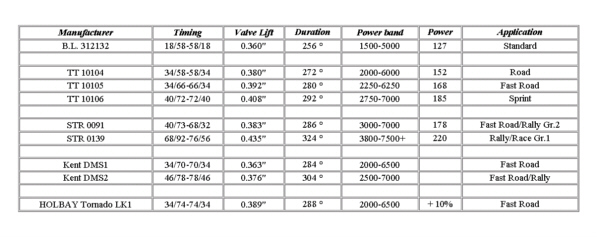

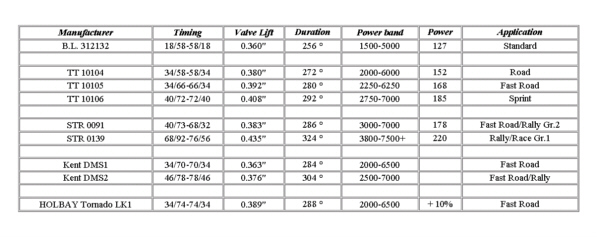

According to the chart below then I would say it had a similar valve lift to the TT10106 (same as mine). Quite a long duration on that profile. Also I suspect it's a regrind rather than a billet cam, so you will need thick shims.

Re: Info on Sprint Cam

Posted: Mon Feb 06, 2012 3:17 pm

by TahitiSPRINT

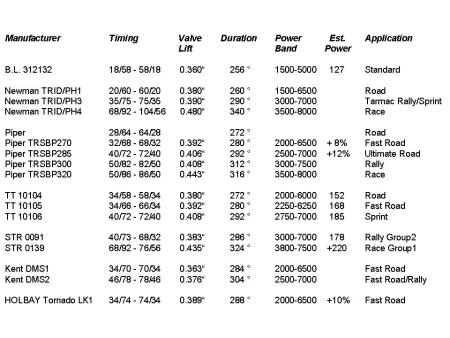

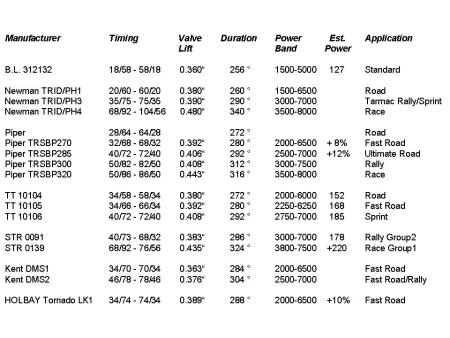

Hi Steve and Mart, I've updated the cams list with Piper and Newman cams:

Hope this helps

Re: Info on Sprint Cam

Posted: Mon Feb 06, 2012 6:45 pm

by Mad Mart

Thanks for that Ronald.

Re: Info on Sprint Cam

Posted: Tue Feb 07, 2012 8:43 am

by Stevecox

Thanks Guys

Mart you can see the weld buildup on the side of the Cams ,

So your right in saying its a regrind , the A measurement on the standard Cam

Is 30.5 mm .

Think I will use my works indexing head and a depth gauge to see if I can get

The opening and dwell angles.

Thanks for the Cam List Ronald

Steve

Re: Info on Sprint Cam

Posted: Tue Feb 07, 2012 7:45 pm

by Mad Mart

Actually I thought the base circle diameter you quoted was near to a standard cam but didn't check. Usually when cams are reground they aren't built up first but simply machined smaller. Like the STR91 I have in my hand, the base circle is approx. 27mm. dia..

Re: Info on Sprint Cam

Posted: Wed Feb 08, 2012 12:41 pm

by Stevecox

Thanks for you're help Mart

What's you're opinion on the TT 10106 Cam for Road use . Or is that type of profile getting up

To Track use only .

Steve

Re: Info on Sprint Cam

Posted: Wed Feb 08, 2012 1:19 pm

by Mad Mart

I don't have any problems using it for normal road use.

Re: Info on Sprint Cam

Posted: Fri Feb 10, 2012 1:18 pm

by Magenta Auto Sprint

I have some concerns about using a cam that has had the lobes built up with weld. Camshafts used to be case hardened, pack a camshaft in a box of carbon granules,seal and heat to about 900 degrees for 5 hours, the carbon is absorbed by the steel to a depth of about 0.040" after grinding the depth is about 0.030. Later camshafts were induction hardened, a much quicker process and just as effective although a different grade of steel forging is used.

so what happens to the hardness when it is built up with weld and can the lobe be re-hardened. Hopefully such camshafts have been proven in the field but if it was me, i would like to know more before fitting the cam to my engine.

Re: Info on Sprint Cam

Posted: Fri Feb 10, 2012 1:33 pm

by longboarder

I used to weld for a living, so can say with some confidence that you can weld with a case hard rod, Big digger bucket teeth was a favourite and many a smelly hour was spent at the local tip rebuilding teeth. This was all stick weld M.A.G. But I do share your concerns, as bits not "stuck" on correctly come adrift and wreck havoc, if it was soft it would just rub away, I suppose its down to the integrity of the cam supplier or even the welder who does this. A lot of my work was examined in the "non destructive test" for flaws etc. Wonder if the cam manufacturer had the technology to do this.