Today started with removing the carbs and manifolds. This time there was absolutely no sign of the manifold gasket starting to fail so a wasted effort maybe? I did find that last time round I'd put a smear of paste on the manifold gasket both sides around the exhaust ports, I'd forgotten that I'd done that. This seems to be good thing to do, this gasket has lasted 16k miles with absolutely no sign of deterioration, the previous one got changed due to total failure at the same milage.

With the manifold off I was able to clean up the faces and stud threads and boy did they need it.

Never been particularly happy with this manifold but is was the only one Winns had in stock the day the previous one died. Further unhappiness came when I trial fitted the downpipe, it wouldn't go all the way on. This is due to the studs not aligning correctly with the holes in the new downpipe.

I'd have to push pretty damn hard to get the downpipe to go on to the unthreaded part of the stud. I was just pondering how to open out the holes in the downpipe when I remembered that the old downpipe had the same problem, it too needed to be forced to go all the way on the studs. Both the gaskets I had in stock, one NOS copper and one new style steel match both the downpipes perfectly but not the manifold. Taking the downpipe with me I went off to Winns and got another manifold, this fits the new downpipe fine.

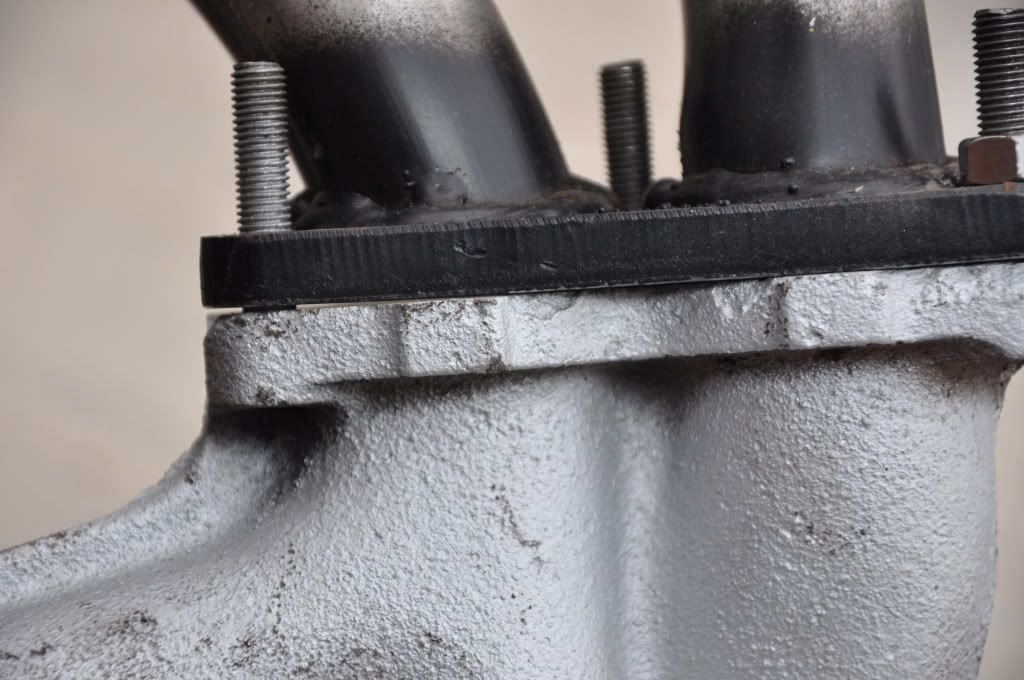

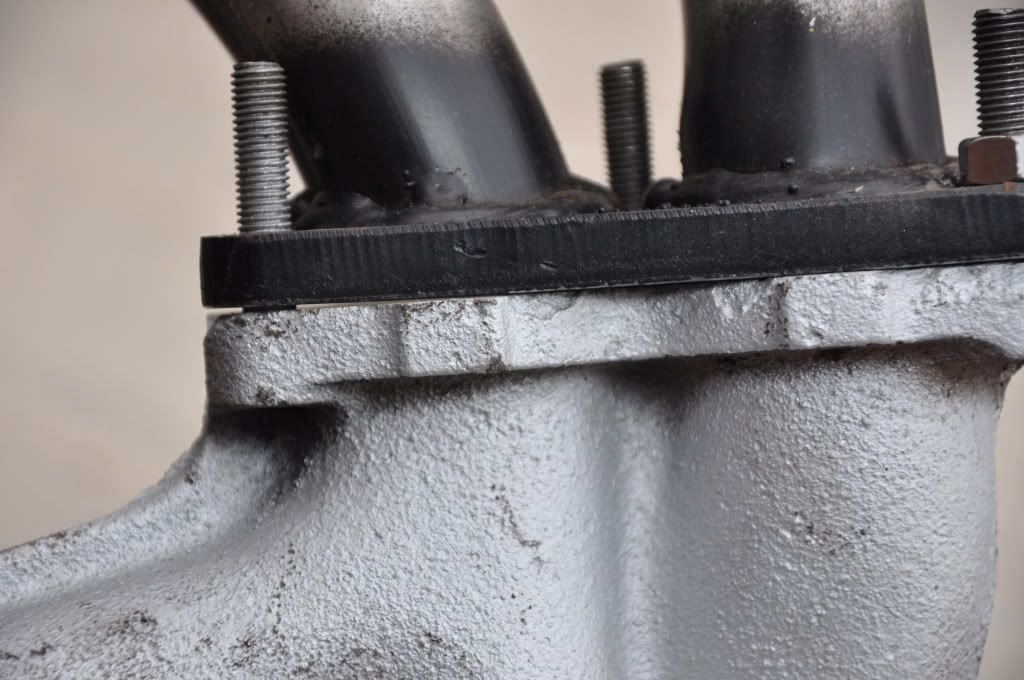

Next job is was to check the flange faces, pretty poor for a first fit.

This was due to some plasma spatter and one protruding pipe end, all quickly cleaned up with the powerfile.

Not much i can do about the flatness though.

Didn't seem too bad though and the fit was much better.

Manifold dry fitted to head:

Next was to dry fit the downpipe at which point the day went distinctly poo. The manifold would not fit by a country mile, I couldn't even get it far enough down to pass onto the studs. In the end the only way I could get the downpipe in was to remove the manifold again and with studs already engaged fit the two together. With the manifold tightened to the head the downpipe was wedged solidly in place with the flanges a mile off mating.

And that's as close as it can get due to clashes with the bell housing, steering and chassis rail.

I popped the old downpipe on to see where it should run, this is how much space there should be by the bell housing and steering coupling:

And down there is clear daylight between the pipe and the chassis rail.

Side by side on the bench it's clear that they are different but not exactly why it's such an appalling fit.

A block of wood and some chalk marks the position of the old pipe.

From above with the flange in the same location the new pipe really isn't far out.

But from the side (which would be above-ish on the car) at the point the pipes pass between the bellhousing and steering joint the difference is stark

It's better a bit further back but still well wrong.

So tomorrow I'll be fitting the old downpipe again and then I'll find out if the rest of the shiny new system is as s##t as the downpipe. I didn't want to mix old with new as I'll be filling the new boxes with rust flakes, this is why I've gone on bodging the back box until I had time to do the job properly. Ah well, if the rest of the stainless system is as s##t as the downpipe the whole lot will be staying on the shelf a while longer and we'll be chugging to cornwall very slowly indeed in Mrs Weevils auto. Maybe I should call in at GES on my way through devon and see if their current production is as p155 poor.

Off to find my dolly mixtures now, didn't Richard Old fit a new exhaust recently?