Well some years ago at Thruxton I saw a racer brought to an expensive engine fail stop and I found out that the engine built by the well known puzzle maker had broken these bolts and the valves had become intimate with the pistons

So when I built my engine I added 2 more M6 bolts (chosen thread to avoid any incorrect assembly) to give peace of mind on a possible fault.

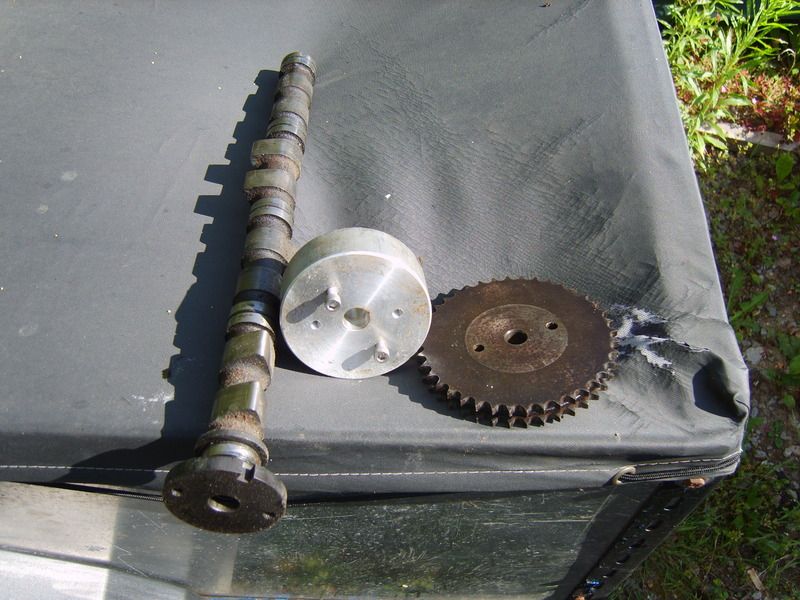

The picture shows a cam sprocket and cam with my drill jig to locate the holes without hitting any vital bits such as the cut out on the cam (correctly spotted Chris).

The jig is used to drill the cam using a pistol drill as the thickness of the jig keeps the drill square to the face and there are two holes to attach the sprocket to the jig to spot that too. I found that the cam is soft and easy to drill and tap.

Eagle eyed spotters among you will see the spigot that sits in the sprocket and locates in the cam is missing as I had not got one when doing the picture.

The next picture shows one of the adjustable cam sprockets that I made a few years ago.

Finally the bottom picture shows my set up when I did the first one.