RUK - Project Recommission 1972 'Dolomite' Auto

-

Jon Tilson

- Guest contributor

- Posts: 11179

- Joined: Tue Oct 03, 2006 9:45 pm

- Location: Middlesex

Re: RUK - Project Recommission 1972 'Dolomite' Auto

Another senior or chemo moment...

Molesworth it is .....

Jonners

Molesworth it is .....

Jonners

Note from Admin: sadly Jon passed away in February 2018 but his humour and wealth of knowledge will be fondly remembered by all. RIP Jonners.

-

Carledo

- TDC Shropshire Area Organiser

- Posts: 7242

- Joined: Sun Aug 21, 2011 5:12 pm

- Location: Highley, Shropshire

Re: RUK - Project Recommission 1972 'Dolomite' Auto

You're quite correct! As eny fule knoe! Wizz for Atoms ect!

I'll have to settle for senior moment!

Steve

'73 2 door Toledo with Vauxhall Carlton 2.0 8v engine (The Carledo)

'78 Sprint Auto with Vauxhall Omega 2.2 16v engine (The Dolomega)

'72 Triumph 1500FWD in Slate Grey, Now with RWD and Carledo powertrain!

Maverick Triumph, Servicing, Repairs, Electrical, Recomissioning, MOT prep, Trackerjack brake fitting service.

Apprentice served Triumph Specialist for 50 years. PM for more info or quotes.

'78 Sprint Auto with Vauxhall Omega 2.2 16v engine (The Dolomega)

'72 Triumph 1500FWD in Slate Grey, Now with RWD and Carledo powertrain!

Maverick Triumph, Servicing, Repairs, Electrical, Recomissioning, MOT prep, Trackerjack brake fitting service.

Apprentice served Triumph Specialist for 50 years. PM for more info or quotes.

Re: RUK - Project Recommission 1972 'Dolomite' Auto

It's the race to be ready for TDCIR on Sunday!

Part 1!

Seats.....

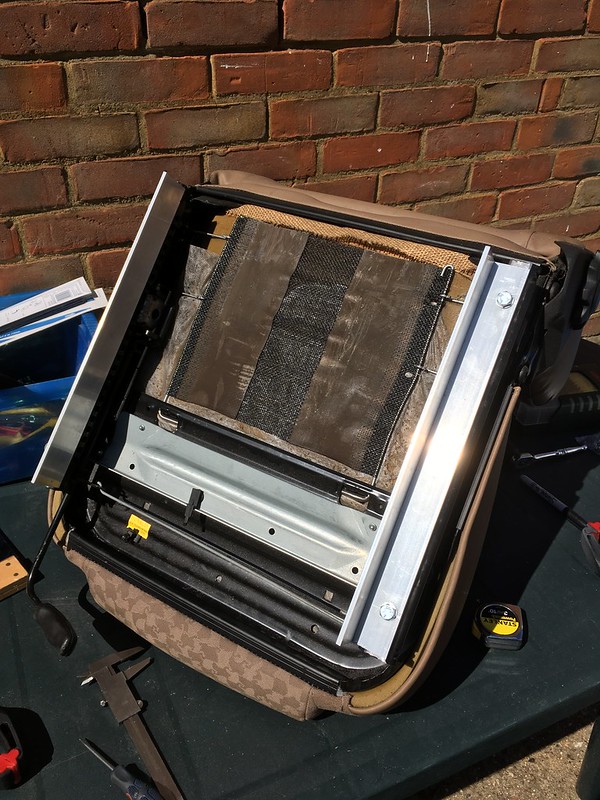

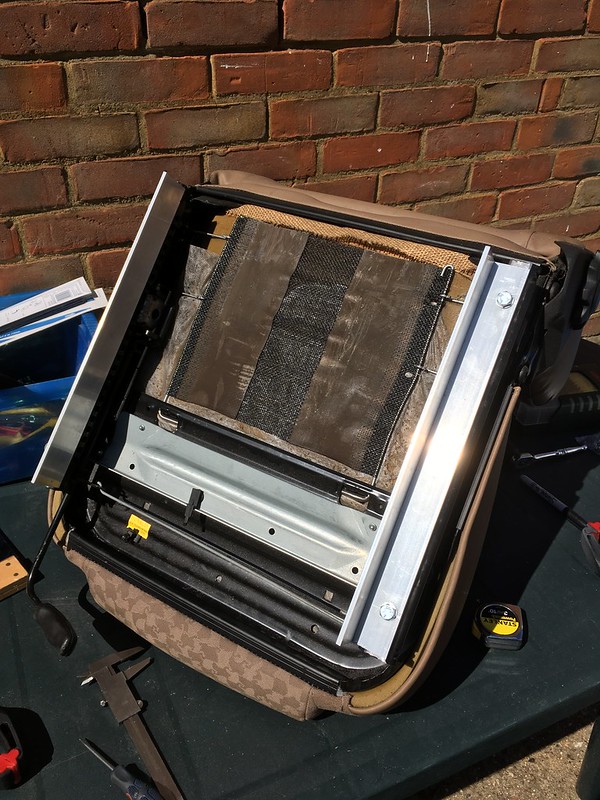

So I have seen numerous posts about people who have fitted different seats to their dolly. So as you know I have a set of brownish beige MGF seats which I am going to fit.

I'm funny about my driving position, the original seats sat central to the steering wheel and a few people who have fitted modern seats seem to have used the inner mounting points and then drilled new outer mountng points or made a bracket to fit to the originals. From what I can fathom this makes the seat sit off centre, this would annoy me so I wanted to avoid that.

I also wanted to avoid welding so people could easily copy me, MGF seats are readily available quite cheap online and are a great fit in my opinion.

So, on with it. Here we have your standard MGF seat, I believe its the "MK2" seat with the slightly raised rear centre section.

The runners are covered with various mounting brackets specific to the MGF

So the first job is to remove all of them...

You will also need to grind back the runner stops as well to allow the bolts to pass and the seat to move backwards and forwards.

If you at these in the car they'd be too low, by about an inch and a half, well for me anyway, others may be different.

To mount them I used 1.5" x 1.5" x 3/16" Aluminium Angle. This give me the height I need plus allows me to angle the front to support my legs.

First thing to do is to mount them to the existing mounting holes in the floorpan.

I found that the optimum width was to set the inner faces to 380mm wide. Everyone's cars will be different so I would make your own measurements to achieve this.

Another length of angle the same size as the one you mounted to the floor is bolted to the runners on the seat, again, I found that seat runner dimensions vary so measure first before drilling.

Drill holes, bolts through.

You have to fit the bolts this way as they wont fit through the runners, I don't like it but the should be fine as I have used nylocs.

Pop the seats in the car for a test fit and to finalise the angle.

Pull them out, disassemble everything, drill holes to mount the two angle sections together. I settled on a 12mm rise which was comfortable for me, sorry I can;t be bothered to go and calculate the angle!

Put them back in the car, loosely bolt everything together and test it fits...

Bolt everything up nice and tight and hey presto we have MGF seats in the RUK, colour almost matches as well!

Extremely comfortable and they sit central to the steering wheel, excuse the mess but rear legroom isn't really affected either. I will add another nut and bolt clamping the angled sections at the recommendation of Bruce to counter any torsional forces but they don't move at all.

Right, part 2 onto the rest of the wiring!

Part 1!

Seats.....

So I have seen numerous posts about people who have fitted different seats to their dolly. So as you know I have a set of brownish beige MGF seats which I am going to fit.

I'm funny about my driving position, the original seats sat central to the steering wheel and a few people who have fitted modern seats seem to have used the inner mounting points and then drilled new outer mountng points or made a bracket to fit to the originals. From what I can fathom this makes the seat sit off centre, this would annoy me so I wanted to avoid that.

I also wanted to avoid welding so people could easily copy me, MGF seats are readily available quite cheap online and are a great fit in my opinion.

So, on with it. Here we have your standard MGF seat, I believe its the "MK2" seat with the slightly raised rear centre section.

The runners are covered with various mounting brackets specific to the MGF

So the first job is to remove all of them...

You will also need to grind back the runner stops as well to allow the bolts to pass and the seat to move backwards and forwards.

If you at these in the car they'd be too low, by about an inch and a half, well for me anyway, others may be different.

To mount them I used 1.5" x 1.5" x 3/16" Aluminium Angle. This give me the height I need plus allows me to angle the front to support my legs.

First thing to do is to mount them to the existing mounting holes in the floorpan.

I found that the optimum width was to set the inner faces to 380mm wide. Everyone's cars will be different so I would make your own measurements to achieve this.

Another length of angle the same size as the one you mounted to the floor is bolted to the runners on the seat, again, I found that seat runner dimensions vary so measure first before drilling.

Drill holes, bolts through.

You have to fit the bolts this way as they wont fit through the runners, I don't like it but the should be fine as I have used nylocs.

Pop the seats in the car for a test fit and to finalise the angle.

Pull them out, disassemble everything, drill holes to mount the two angle sections together. I settled on a 12mm rise which was comfortable for me, sorry I can;t be bothered to go and calculate the angle!

Put them back in the car, loosely bolt everything together and test it fits...

Bolt everything up nice and tight and hey presto we have MGF seats in the RUK, colour almost matches as well!

Extremely comfortable and they sit central to the steering wheel, excuse the mess but rear legroom isn't really affected either. I will add another nut and bolt clamping the angled sections at the recommendation of Bruce to counter any torsional forces but they don't move at all.

Right, part 2 onto the rest of the wiring!

Re: RUK - Project Recommission 1972 'Dolomite' Auto

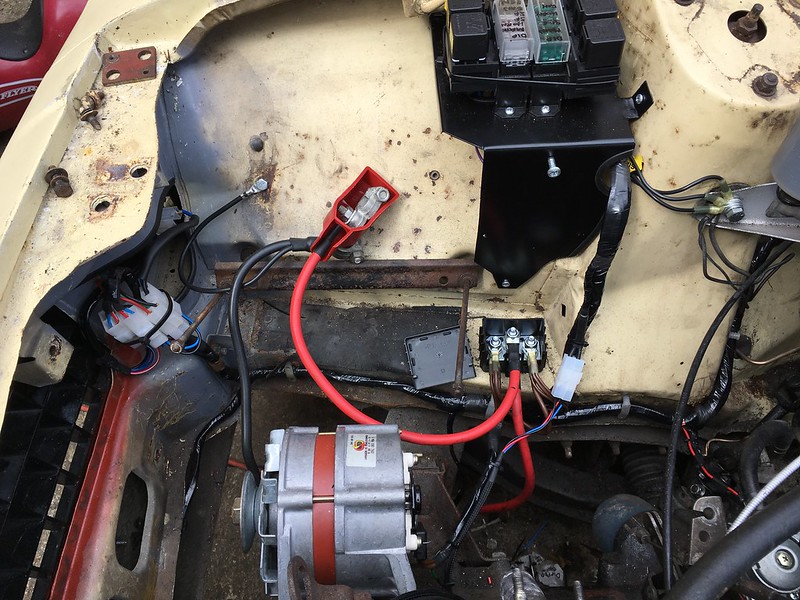

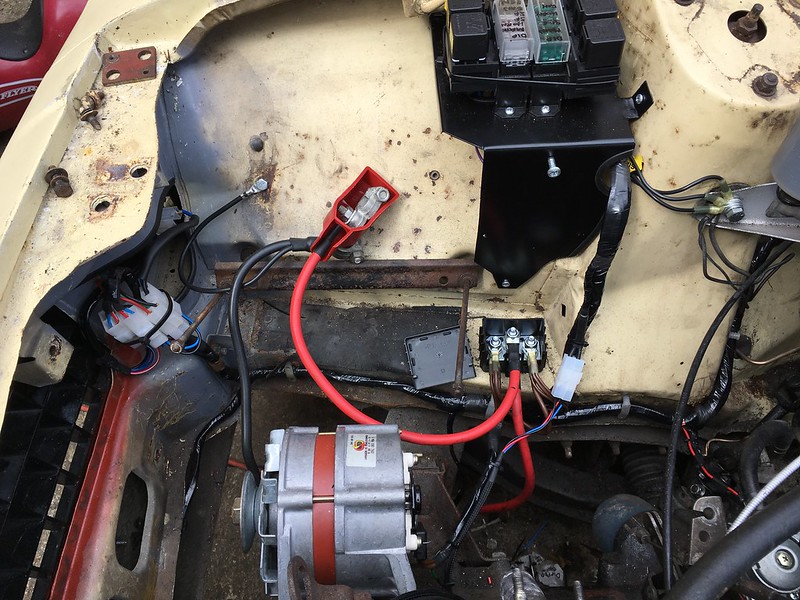

Part 2 - finish the wiring!

I have ditched the bullet connectors on the front of the car for connector blocks. I'm not sure if they are the best but they seem to be up to the job, time will tell.

So with everything tested and working I wrapped the loom and attached it to the body.

I'm quite pleased, it looks quite factory!

I double checked and the relays don't touch the bonnet, it's close but they are clear by about 4mm.

The sidelights work really well, the camera makes them look more bluey green than they really are...

On to the cooling system, Volvo 850 header tank ready to be fitted...

I copied Tony Burds fitting position because It looks rather neat. It's just higher than the thermostat, needs a recess cut in the bonnet reinforcer to clear the cap otherwise I think it rubs. It needs another bracket to support it.

It's connected via a t piece to the bottom hose, I re-did this with a new hose to get the join closer to the rad then wrapped the hose in plastic spiral to protect it, it needs a P clip to attach it to the bottom of the rad, it clears the crank pulley though.

Kenlowe plumbed in, it's close to the air box so I may reroute that top hose, for now the plastic will protect it.

New stainless return hose from Chris Witor...

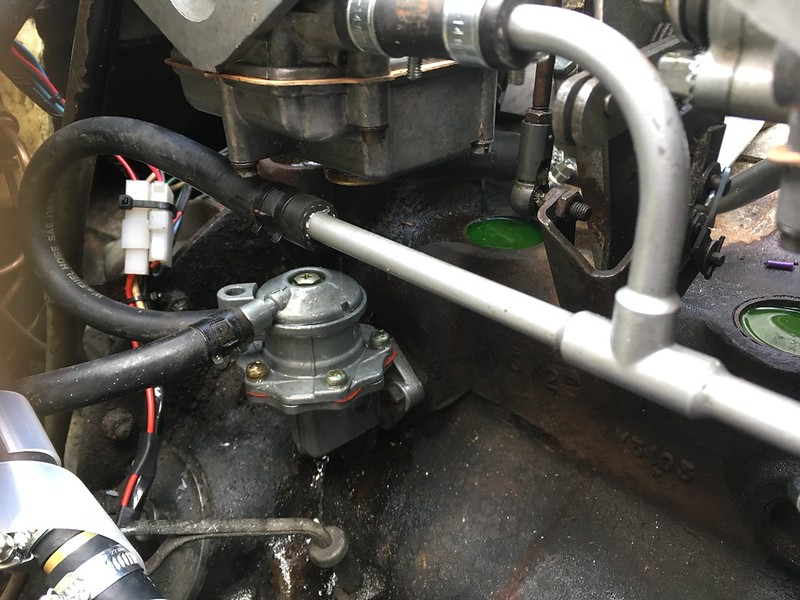

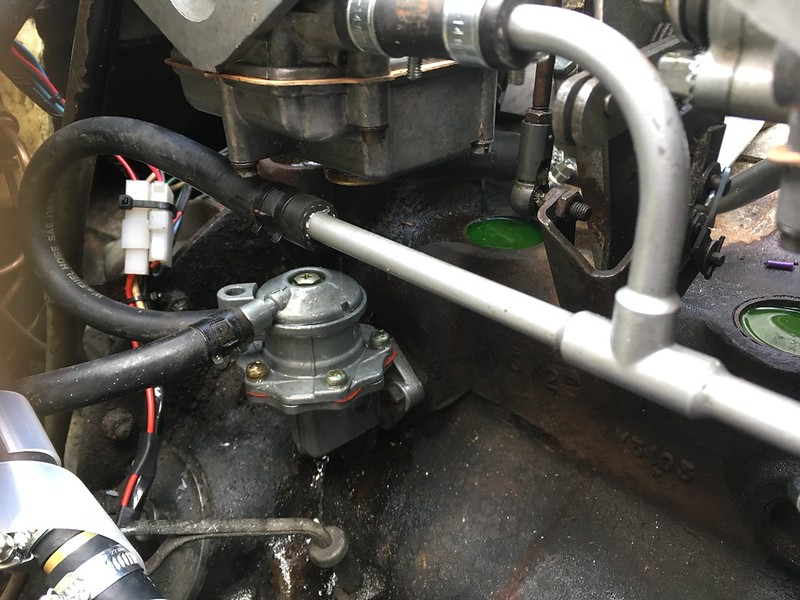

Carbs on, cooling system filled, ready for a start up!

Well that was an anticlimax, no not a cooling leak, that was my lack of control with the antifreeze container! The rubbers on the float chamber plugs are shot and fuel is dripping out of them. Bugger! The only thing I didn't replace! That'll teach me!

New pair ordered and the carbs will have to come off to do them properly. Not too worry, it's an easy job.

Left to do for TDCIR.

Recess bonnet, support header tank properly.

Remove exhaust and refit fixing manifold blow

Carbs - float plug and tune

Set fan cut in.

Change oil

Tracking

Finish rear brake light

Fit new mirrors

Give it a run, hopefully Saturday.

Feeling the heat!

I have ditched the bullet connectors on the front of the car for connector blocks. I'm not sure if they are the best but they seem to be up to the job, time will tell.

So with everything tested and working I wrapped the loom and attached it to the body.

I'm quite pleased, it looks quite factory!

I double checked and the relays don't touch the bonnet, it's close but they are clear by about 4mm.

The sidelights work really well, the camera makes them look more bluey green than they really are...

On to the cooling system, Volvo 850 header tank ready to be fitted...

I copied Tony Burds fitting position because It looks rather neat. It's just higher than the thermostat, needs a recess cut in the bonnet reinforcer to clear the cap otherwise I think it rubs. It needs another bracket to support it.

It's connected via a t piece to the bottom hose, I re-did this with a new hose to get the join closer to the rad then wrapped the hose in plastic spiral to protect it, it needs a P clip to attach it to the bottom of the rad, it clears the crank pulley though.

Kenlowe plumbed in, it's close to the air box so I may reroute that top hose, for now the plastic will protect it.

New stainless return hose from Chris Witor...

Carbs on, cooling system filled, ready for a start up!

Well that was an anticlimax, no not a cooling leak, that was my lack of control with the antifreeze container! The rubbers on the float chamber plugs are shot and fuel is dripping out of them. Bugger! The only thing I didn't replace! That'll teach me!

New pair ordered and the carbs will have to come off to do them properly. Not too worry, it's an easy job.

Left to do for TDCIR.

Recess bonnet, support header tank properly.

Remove exhaust and refit fixing manifold blow

Carbs - float plug and tune

Set fan cut in.

Change oil

Tracking

Finish rear brake light

Fit new mirrors

Give it a run, hopefully Saturday.

Feeling the heat!

- Triumph1300

- TDC Member

- Posts: 1500

- Joined: Wed Sep 27, 2006 10:59 am

- Location: Coventry

Re: RUK - Project Recommission 1972 'Dolomite' Auto

You can do it, I'm looking forward to seeing this on Sunday

BWJ

1966 Triumph 1300 Royal Blue

1966 Triumph 2000 Blue

1965 Triumph 2000 black and rust

1967 BSA B40wd green

2018 Jaguar E pace 2018

NOBODY expects the Canley Inquisition!

1966 Triumph 1300 Royal Blue

1966 Triumph 2000 Blue

1965 Triumph 2000 black and rust

1967 BSA B40wd green

2018 Jaguar E pace 2018

NOBODY expects the Canley Inquisition!

Re: RUK - Project Recommission 1972 'Dolomite' Auto

At your speed James, waiting for the posted items will be

the greatest delay.

the greatest delay.

NRW 581W Sprint

On the motorway no one can hear me sing!

Construed as a public service, self preservation in reality.

On the motorway no one can hear me sing!

Construed as a public service, self preservation in reality.

-

Jon Tilson

- Guest contributor

- Posts: 11179

- Joined: Tue Oct 03, 2006 9:45 pm

- Location: Middlesex

Re: RUK - Project Recommission 1972 'Dolomite' Auto

Oh and paint camshaft cover.....

You have your standards.....

Lovely job...and a bummer on the plugs. I missed them too when you did the rebuild....

Jonners

You have your standards.....

Lovely job...and a bummer on the plugs. I missed them too when you did the rebuild....

Jonners

Note from Admin: sadly Jon passed away in February 2018 but his humour and wealth of knowledge will be fondly remembered by all. RIP Jonners.

Re: RUK - Project Recommission 1972 'Dolomite' Auto

Yes sir!Oh and paint camshaft cover.....

I put new O rings on the plugs and started it up this morning - no leaks! I didn't even have to take of the carbs either.

I warmed her up, even out of tune the carbs feel so much better, I'm wondering if there was always some leakage from the float chambers, not too worry I'm excited to get it tuned now.

Whilst warmed up I set the fan to cut in, this will probably need some fine tuning when the weather is warmer.

I'll do the tracking when I fit my trackerjack brakes as I'll have to crack off the nuts and I may have to put new rod ends on. The tracking's ok, it was just a belt and braces approach really.

So that's three jobs off the list. I'll do the exhaust next, weather is supposed to be better tomorrow.

- SprintMWU773V

- TDC Staffs Area Organiser

- Posts: 5429

- Joined: Wed Oct 18, 2006 2:08 pm

- Location: The Old Asylum

Re: RUK - Project Recommission 1972 'Dolomite' Auto

I can't come to TDCIR as I'm at a wedding this weekend but I hope you get it there and look forward to seeing some pics.

Mark

1961 Chevrolet Corvair Greenbrier Sportswagon

1980 Dolomite Sprint project using brand new shell

2009 Mazda MX5 2.0 Sport

2018 Infiniti Q30

1961 Chevrolet Corvair Greenbrier Sportswagon

1980 Dolomite Sprint project using brand new shell

2009 Mazda MX5 2.0 Sport

2018 Infiniti Q30

Hmm….

The reason I sited the header tank next to the heater's blower is that this is the highest position that can be achieved on the nearside.James467 wrote: ↑Tue Aug 29, 2017 8:46 pm On to the cooling system, Volvo 850 header tank ready to be fitted...

I copied Tony Burds fitting position because It looks rather neat. It's just higher than the thermostat, needs a recess cut in the bonnet reinforcer to clear the cap otherwise I think it rubs. It needs another bracket to support it.

This takes advantage of the space within the bonnet's skeleton so no cutting is required. I made a bracket to use the header tank's own mounting slot.

The entire contents of the header tank are above the thermostat and therefore, should the level drop, the low level sensor will be triggered

before the level drops within the engine.

Ian.

TDC Forum moderator

PLEASE help us to maintain a friendly forum,

either PM or use Report Post if you see anything you are unhappy with. Thanks.

PLEASE help us to maintain a friendly forum,

either PM or use Report Post if you see anything you are unhappy with. Thanks.

Re: Hmm….

I don't like your fitting position because it hinders access to the plugs, also mine looks neater.sprint95m wrote: ↑Wed Aug 30, 2017 1:55 pmThe reason I sited the header tank next to the heater's blower is that this is the highest position that can be achieved on the nearside.James467 wrote: ↑Tue Aug 29, 2017 8:46 pm On to the cooling system, Volvo 850 header tank ready to be fitted...

I copied Tony Burds fitting position because It looks rather neat. It's just higher than the thermostat, needs a recess cut in the bonnet reinforcer to clear the cap otherwise I think it rubs. It needs another bracket to support it.

This takes advantage of the space within the bonnet's skeleton so no cutting is required. I made a bracket to use the header tank's own mounting slot.

The entire contents of the header tank are above the thermostat and therefore, should the level drop, the low level sensor will be triggered

before the level drops within the engine.

Ian.

With a bonnet cutout it should sit about 1mm from the bonnet skin.

Re: RUK - Project Recommission 1972 'Dolomite' Auto

That was me being sarcastic btw!

Sometimes doesn't come across very well on a forum!

Sometimes doesn't come across very well on a forum!

-

new to this

- TDC Member

- Posts: 1792

- Joined: Mon Dec 12, 2016 9:53 pm

- Location: Harrow Middlesex

Re: RUK - Project Recommission 1972 'Dolomite' Auto

James

you have done a neat job fitting the seats,are you going to change the back seat as well

Dave

you have done a neat job fitting the seats,are you going to change the back seat as well

Dave

-

Karlos

Re: Hmm….

Ian's position is better as it contributes to more even front/rear weight distribution.James467 wrote: ↑Wed Aug 30, 2017 2:54 pmI don't like your fitting position because it hinders access to the plugs, also mine looks neater.sprint95m wrote: ↑Wed Aug 30, 2017 1:55 pmThe reason I sited the header tank next to the heater's blower is that this is the highest position that can be achieved on the nearside.James467 wrote: ↑Tue Aug 29, 2017 8:46 pm On to the cooling system, Volvo 850 header tank ready to be fitted...

I copied Tony Burds fitting position because It looks rather neat. It's just higher than the thermostat, needs a recess cut in the bonnet reinforcer to clear the cap otherwise I think it rubs. It needs another bracket to support it.

This takes advantage of the space within the bonnet's skeleton so no cutting is required. I made a bracket to use the header tank's own mounting slot.

The entire contents of the header tank are above the thermostat and therefore, should the level drop, the low level sensor will be triggered

before the level drops within the engine.

Ian.

With a bonnet cutout it should sit about 1mm from the bonnet skin.

(That is me being sarcastic.)

I am addicted to this thread, good luck for Sunday.

(That is not me being sarcastic)

Re: RUK - Project Recommission 1972 'Dolomite' Auto

I'm confused. RUK isn't always RUK.

Jeroen.

Jeroen.

Classic Kabelboom Company. For all your wiring needs. http://www.classickabelboomcompany.com