Page 1 of 1

Distributor shaft movement.

Posted: Wed Apr 29, 2015 8:36 pm

by Reg

Hi folks. How much up and down "play" is the norm..or should there be none at all?

The one on the car at the moment has around 3mm of play.

I have a spare dizzy with around 1mm play.

The reason I ask is that, my magnetronic disc has started to touch and quite badly foul the module. I now think that this is the problem why my Sprint will start with no problems at all, then hesitate a bit, then when it's put into drive , will promptly cut out!..making it un-driveable..

Any idea's?..thanks in advance.

Re: Distributor shaft movement.

Posted: Thu Apr 30, 2015 12:29 am

by Jon Tilson

3mm up and down is far too much and will also damage the contacts in the dizzy cap.

Use the other dizzie....and I agree I think you have found it.

Jonners

Re: Distributor shaft movement.

Posted: Fri May 01, 2015 4:13 pm

by MIG Wielder

I think you can adjust the up/down play with the thrust washer at the base of the distributor above the cog; Adding a small shim washer should fix that. Trouble is there is no spec; in either workshop manual for the allowable play. There may also be side-to-side play caused by wear in the shaft / bush of course. This would be important for some electronic ignitions.

Tony.

Re: Distributor shaft movement.

Posted: Fri May 01, 2015 8:25 pm

by Reg

Thanks for the advice chaps.

I have changed the rogue one for the spare, it works well thankfully with no play at all, and crucially the magnetronic disc now stays away from the module to the tune of a healthy 1-2mm.

Tony, I had a quick look at the worn dizzy once it was out the car. The lower part has no movement at all, the upper part however has 3mm up and down but no side to side movement. Is it supposed to be one complete spindle, or two, or has mine broken inside the body? All these questions!

Will have to check it over, test run, fettle with the timing and generally make ready for the mot next week..

Thanks again.

Re: Distributor shaft movement.

Posted: Sun May 03, 2015 11:40 am

by MIG Wielder

Hi Reg, I dug out my old Sprint distributor yesterday from the junk box and that one is like the old one you described. It has about 25 thou of up-down movement at the cog end, and if you take that out with a feeler gauge below the thrust washer there is also 3mm of up and down movement at the top-end. Yes, the shaft is in 2 co-axial pieces to allow the centrifugal and vacuum advance / retard to work, but I hadn't noticed that movement before. Worse of all the top end of the shaft has a lot of side-to-side movement. Which is probably why it ended up in the junk-box. Having read Mart's interesting posting on fixing the side to side play I will probably dismantle it and have a look.

viewtopic.php?f=4&t=29069

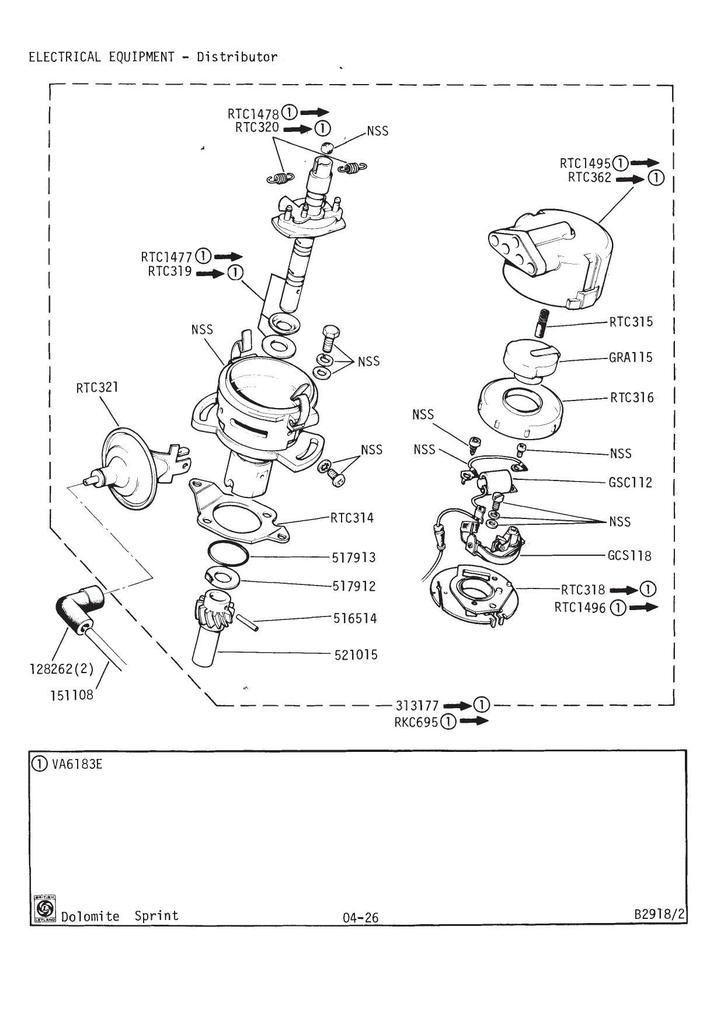

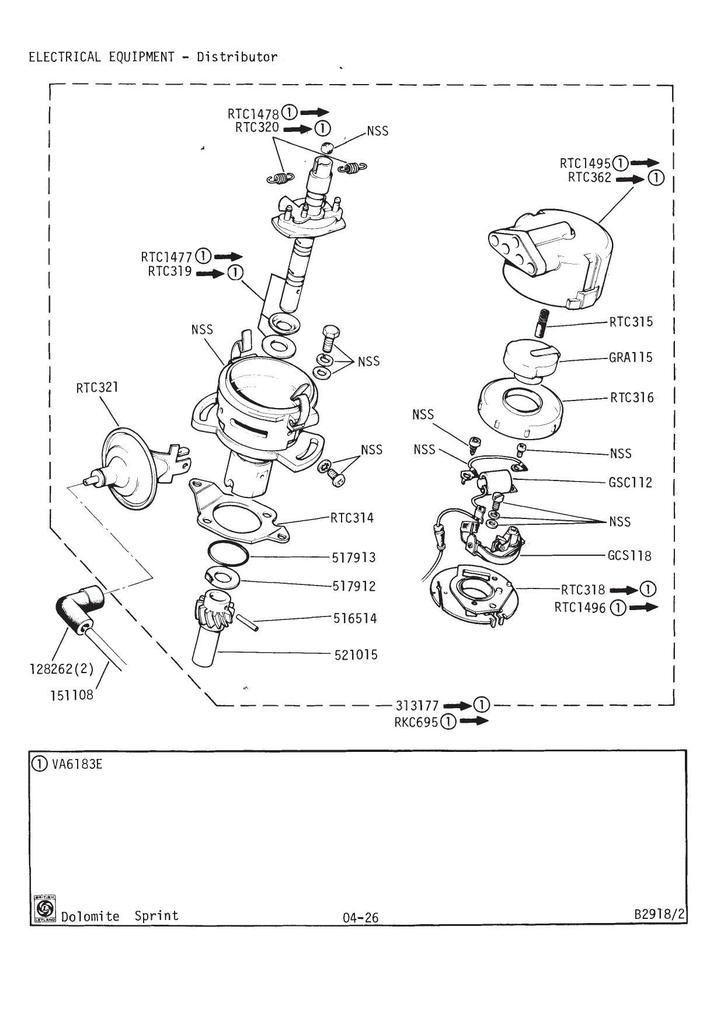

Looking at page 1N 08R of the Sprint parts book there is an exploded view of the various bits. There seems to be a lower thrust washer above the cog but also 2 extra ones at the top end of the shaft both labelled "NSS " -Not Supplied separately. And no set-up procedure in the manual either. I reckon these top washers may set the axial end-float. This may be why some owners have trouble with some electronic ignitions. The magnet moves too far up and down relative to the sensor.

More later ......

Tony.

Re: Distributor shaft movement.

Posted: Sun May 03, 2015 2:08 pm

by MIG Wielder

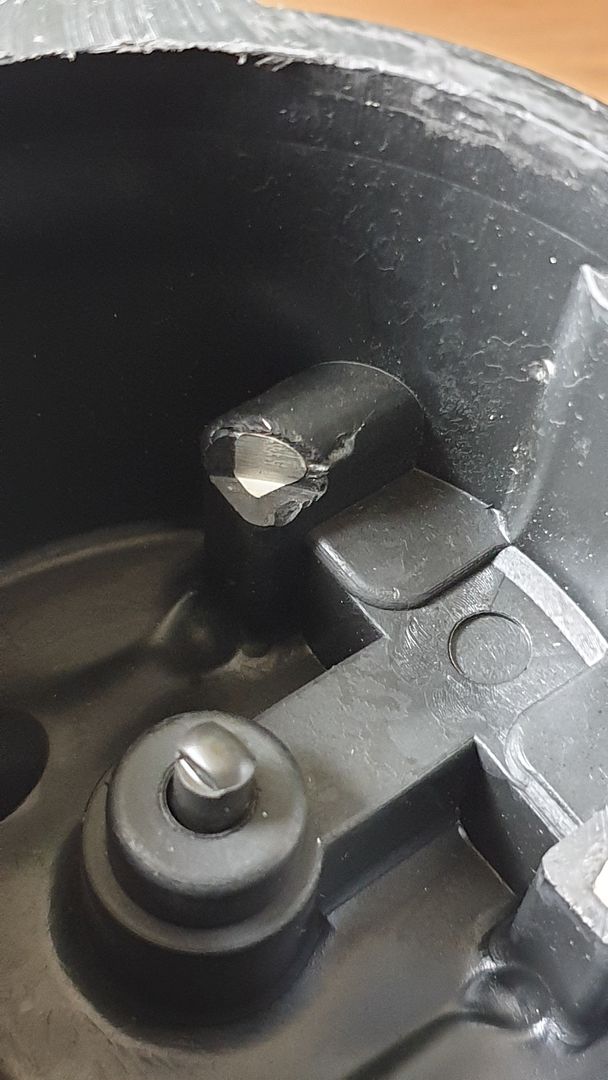

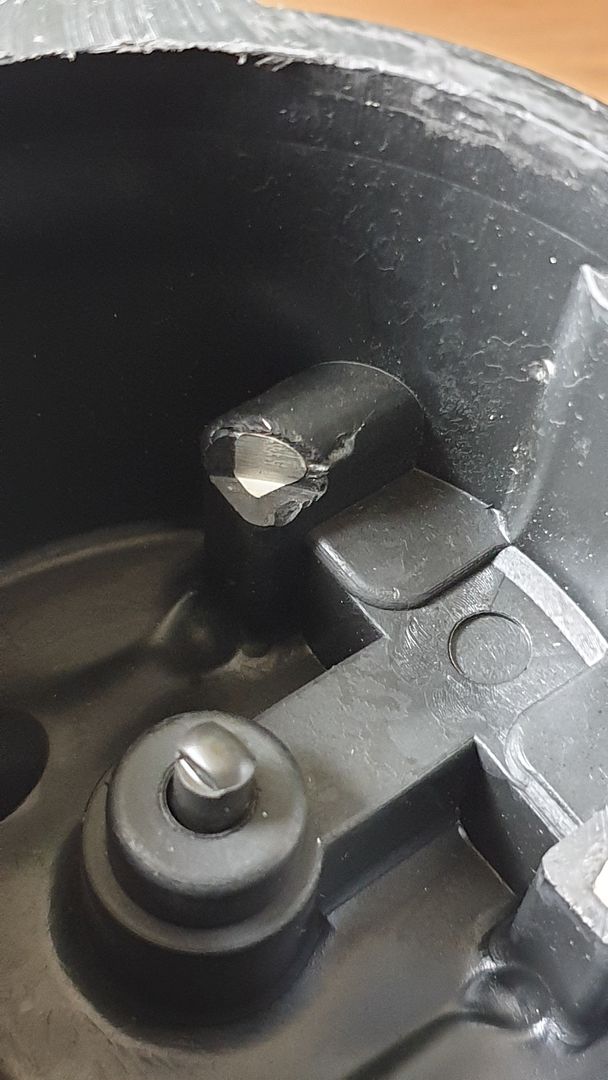

While it was raining I thought I'd dismantle this old distributor and have a look-see.

I got this far .....

- Sprint dizzy shaft.JPG (69.26 KiB) Viewed 2968 times

...and right now I can't see how to separate the 2 halves of the shaft. I thing it is something to do with this collar you can see in the end of the shaft where the rotor arm goes. I was expecting a circlip or similar; it obviously comes off from the top.

Any ideas please ?

- Sprint dizzy shaft end.JPG (72.06 KiB) Viewed 2968 times

Tony.

Re: Distributor shaft movement.

Posted: Sun May 03, 2015 4:07 pm

by Mad Mart

I've just done it on an old dizzy Tony, although the springs were missing. Apart from a small nylon bush in the top, it just slid off.

Re: Distributor shaft movement.

Posted: Sun May 03, 2015 4:21 pm

by Toledo Man

Is this of any help?

Re: Distributor shaft movement.

Posted: Fri May 08, 2015 9:03 pm

by Reg

Ok, an update. As well as changing the dizzy, I found that one of the carb breather pipes had split underneath, popped into Moss europe and got a pair of sturdy new ones..much thicker rubber than the old ones. Added to that, I found that two of the HT leads (done less than 5000 miles) were breaking down. I changed them for two old used spares and it ran so much better!

I'm totally sick of the utter crap forced on us that suppliers call 'quality' parts..I've ordered a set of Magnecor leads..may not look original, but I would much rather the bloody thing ran properly.

Oh, and finally..it passed it's mot today!

Re: Distributor shaft movement.

Posted: Fri May 08, 2015 10:05 pm

by Toledo Man

Wasn't one of the Fitchett's (aka "Mr-retro-leads-plugs") doing decent quality HT leads. His thread is

HERE. You're right about poor quality parts. If we demand decent quality parts then we must pay the price.

Re: Distributor shaft movement.

Posted: Sat May 09, 2015 9:52 am

by Reg

Toledo Man wrote: You're right about poor quality parts. If we demand decent quality parts then we must pay the price.

Absolutely agree, and so we should! Sometimes though, we have no other option than to buy shite..

Magnecore leads (set of 5) have a 10 year guarantee..and were £64..pretty cheap for quality I thought. They have had a lot of rave reviews, I have never used them before, so we'll see in time.

Re: Distributor shaft movement.

Posted: Sun May 24, 2015 5:29 pm

by MIG Wielder

Mad Mart wrote:I've just done it on an old dizzy Tony, although the springs were missing. Apart from a small nylon bush in the top, it just slid off.

Thanks for that Mart . I got back onto this mini-project today and I found the following.

Yes, that top bit ( shown in Dave's parts list ) is indeed a nylon cap. Mine was very difficult to remove and I reckon I have ruined it in getting it off. I can see what it does. When the distributor is assembled there is a nylon washer with location tags for the "4-sided-cam bit" ( whatever it is called) and the up and down endfloat between the 2 co-axial top bits is controlled by how hard this top nylon cap is pushed down on the top of the shaft. So if there is a lot of movement up and down the lower nylon bush has worn or this top nylon cap has.

A solution: This nylon cap can be replaced by a couple of washers to set the end float and a circlip to keep it all together.

I found some brass washers of almost exactly the right size:

O.D. = 10.00 mm I.D. 4.78 mm ( or 5mm ).

Circlip I.D. = 0.153 mm or 3.92 mm. ( Probably 4mm will be O.K. ) O.D. < 10mm )

I'll see if I can get some next week.

Then I will have a good spare distributor.

Re: Distributor shaft movement.

Posted: Sun Jul 12, 2015 6:12 pm

by MIG Wielder

Most successful ! I got the necessary circlips and washers at yesterdays Woodcote Rally. I needed 3 washers plus the circlip and this reduced the top-half end float to about 25 thou. Yes it was a bit of a fiddle fitting the circlip but I got there. This is why Lucas probably fitted this nylon end cap; for speed of assembly.

Tony.

Re: Distributor shaft movement.

Posted: Tue Aug 13, 2019 11:16 am

by shaunroche

Talk about a thread resurrection!

I'm having a problem with missing on my Sprint: when setting off and going to 6500rpm in all gears all is fine until I change into 4th gear. It then goes onto what can only be described as like dropping onto three cylinders.

We've checked all the fuel system and supply but

I've always felt it was electricity related.

I recently removed the dizzy cap and found the following damage. Upon putting a new cap on and running it at an event, it looks like similar damage is occurring.

I didn't think to check for axial movement I.e. oscillation, but there does seem to be a lot of movement up and down.

I have a spare dizzy and I'll measure that at the weekend but any thoughts would be appreciated.

Looking at those pictures it looks as though the rotor arm is 'jumping' up and down and clattering the cap.

It's an Ambassador cap btw on a powerspark electronic ignition which up until now, has worked faultlessly...I've recently thought that the cap was made from rubbish material but now realise it may be the vertical movement...

Re: Distributor shaft movement.

Posted: Wed Aug 14, 2019 5:22 pm

by shaunroche

Could anyone suggest what bits I should get from the Distributor Doctor to carry out a restoration then please?

I have a spare dizzy with around 1mm play.

I have a spare dizzy with around 1mm play.