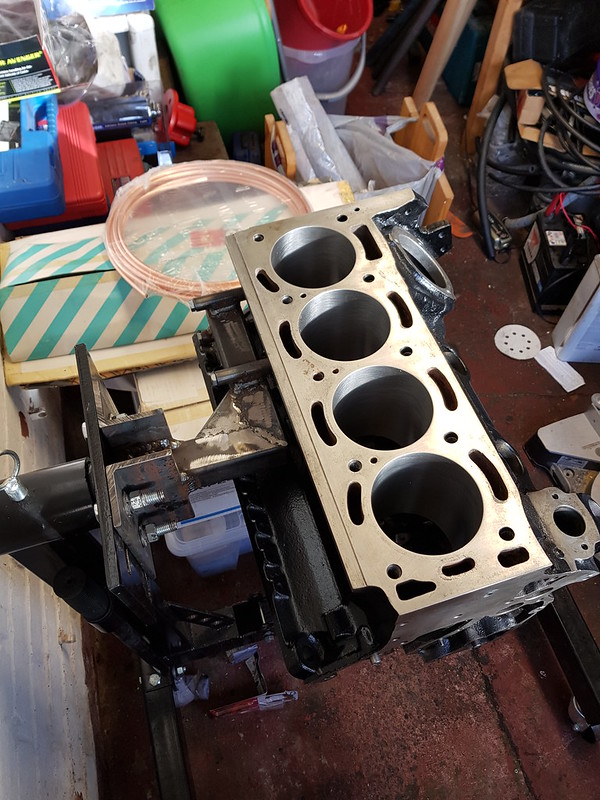

After a bit of work and research I have settled on this design... The design credits go to Jeroen Rothman.

The benefit of using this design is that the block deck is mounted horizontally, therefore making the head easier to work on.

It also allows you to work on all areas of the engine uninhibited.

Due to the way that it has been designed the engine is balanced in the stand now and is very easy to rotate.

Despite looking flimsy it is rock solid when a fully dressed 1850 engine was mounted to it.

I have been testing it today by removing the head of an 1850 and it was very good.

I can make these and be able to sell them for £35 plus postage each to club members. This takes in to account materials, (steel, welding consumables, gas etc...) and my time. I use thick steel box section hence the expense, anything else will just twist. They take about 2 hours each to make and due to the steel gauge that I am using you do need a good welder and a good weld to make sure that the joints are strong enough.

It would be good to gauge interest with a view to making a batch.