some news from "my" Garage...Dolly 1850 related....

-

GinettaG15

- Guest contributor

- Posts: 79

- Joined: Sun Oct 16, 2022 7:12 pm

some news from "my" Garage...Dolly 1850 related....

Chistmas time...work free time...so time for spannering.

my to-do list:

- replace lower steering joint for u-joint --> done

- replace rubber carb mounts against alloy club-mounts--> done

- replace damaged/old waxstat-jets againt new waxstat-ones --> done

- remove starter-motor to investgate intermittent fault of solenoid not working --> done, but result still not satisfying

- change Delco Dizzy D302 from points to hall-efect module --> not done yet*

- change Ingition-coil --> done (Lucas Sports Ballast)

so after having replaced my carb mounts, i started the engine and tried so set the carbs...lumpy idle, impossible to set properly.

investigated and found that the front needle was "modified" with a file...shock!!! it looks like the former car-owner tried to compensate the leaking rubber-carb mount by "improving" the needle-profile, to get it richer.

ok...new needles ordered and fitted.

new Needles are ABT, which are slightly richer than the original ABK

http://www.mintylamb.co.uk/suneedle/

balanced and set the carbs....but i was still not perfectly happy with idling and the first test-drive was not promising:

poor in power, had to pull the choke etc.

i was already wondering why i had to weaken the mixture to bring down the idle-speed on a normal level.....and the reason was clear when starting with my Dizzy:

ok i thought, before doing anything further on the carbs, i should first bring the ignition right:

strobelamp connected....during idle (~900rpm): 17degress B4 TDC --> ok, to much advance = idle speed too high.

so lets adjust the dizzy:

spanners out and first i thought that i had choosen the wrong sized spanner, as i could not feel any resistance during opening the 2 bolts. but the spanner-size was correct....both bolts were only hand-tight(!!!).....this concerned me already

*ok, i thought...before doing further adjustments, lets remove the dizzy straight away, convert it to the electronic module and than start from zero.

i removed the 2 bolts, pulled on the dizzy...nothing...

tried to rotate the dizzy--> rock solid

used penetratng oil, heat, penetrating oil --> rock-solid

gave some tabs with the hammer --> nothing.

left it over night with further penetrating oil...and lets see today.

(as pre-causion i already ordered a 2nd hand dizzy...because my inner-feeling says: this dizzy is so stuck, it wont come out without damaging it)

my to-do list:

- replace lower steering joint for u-joint --> done

- replace rubber carb mounts against alloy club-mounts--> done

- replace damaged/old waxstat-jets againt new waxstat-ones --> done

- remove starter-motor to investgate intermittent fault of solenoid not working --> done, but result still not satisfying

- change Delco Dizzy D302 from points to hall-efect module --> not done yet*

- change Ingition-coil --> done (Lucas Sports Ballast)

so after having replaced my carb mounts, i started the engine and tried so set the carbs...lumpy idle, impossible to set properly.

investigated and found that the front needle was "modified" with a file...shock!!! it looks like the former car-owner tried to compensate the leaking rubber-carb mount by "improving" the needle-profile, to get it richer.

ok...new needles ordered and fitted.

new Needles are ABT, which are slightly richer than the original ABK

http://www.mintylamb.co.uk/suneedle/

balanced and set the carbs....but i was still not perfectly happy with idling and the first test-drive was not promising:

poor in power, had to pull the choke etc.

i was already wondering why i had to weaken the mixture to bring down the idle-speed on a normal level.....and the reason was clear when starting with my Dizzy:

ok i thought, before doing anything further on the carbs, i should first bring the ignition right:

strobelamp connected....during idle (~900rpm): 17degress B4 TDC --> ok, to much advance = idle speed too high.

so lets adjust the dizzy:

spanners out and first i thought that i had choosen the wrong sized spanner, as i could not feel any resistance during opening the 2 bolts. but the spanner-size was correct....both bolts were only hand-tight(!!!).....this concerned me already

*ok, i thought...before doing further adjustments, lets remove the dizzy straight away, convert it to the electronic module and than start from zero.

i removed the 2 bolts, pulled on the dizzy...nothing...

tried to rotate the dizzy--> rock solid

used penetratng oil, heat, penetrating oil --> rock-solid

gave some tabs with the hammer --> nothing.

left it over night with further penetrating oil...and lets see today.

(as pre-causion i already ordered a 2nd hand dizzy...because my inner-feeling says: this dizzy is so stuck, it wont come out without damaging it)

-

GinettaG15

- Guest contributor

- Posts: 79

- Joined: Sun Oct 16, 2022 7:12 pm

Re: some news from "my" Garage...Dolly 1850 related....

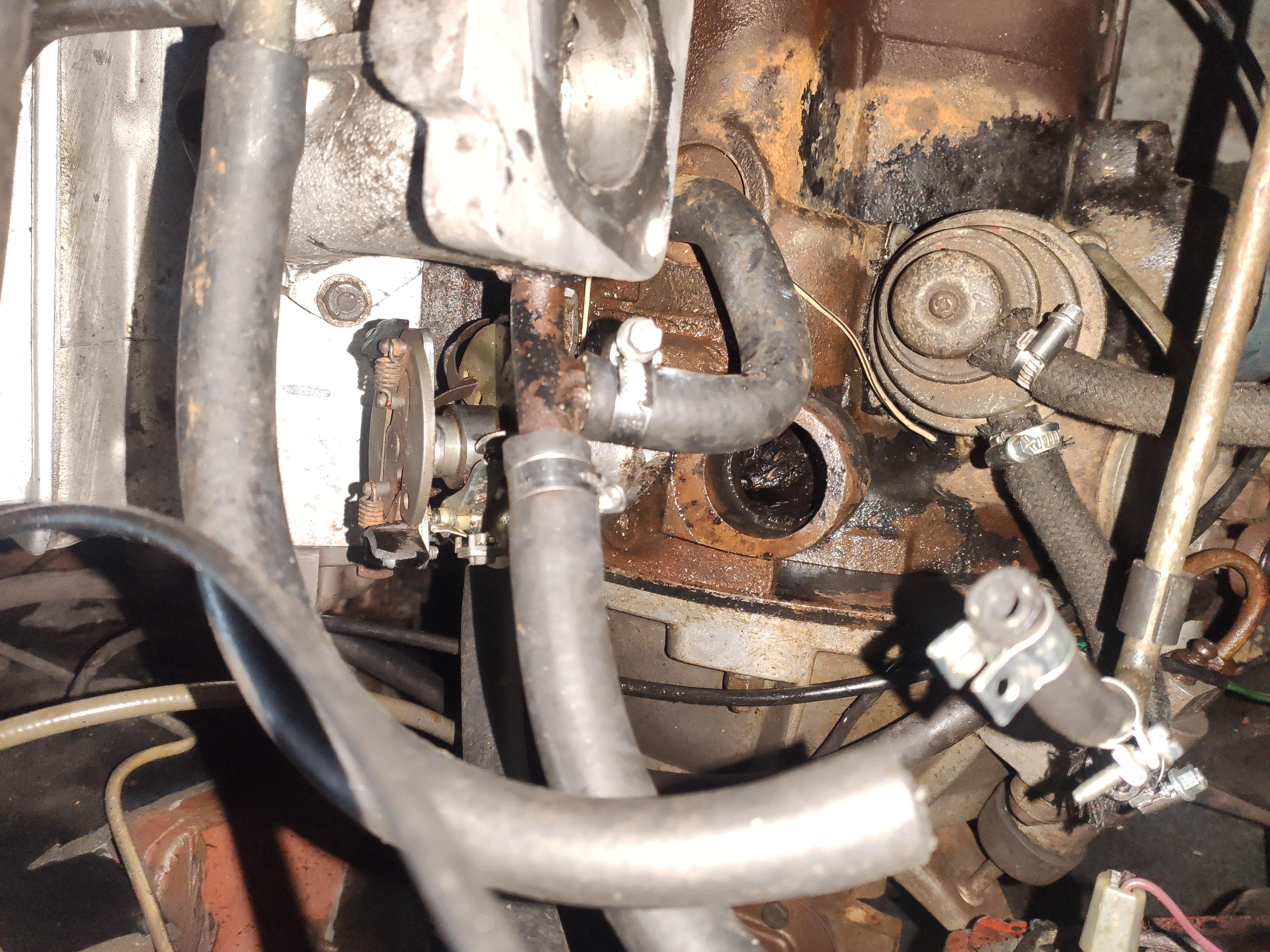

the today´s result is fustrating:

the Dizzy´s alloy housing is broken into several pieces...at least the remainings are now unseized and can be rotated inside the engine´s block.

but: the dizzy still doos not come off the block. the alloy casing can be lifted a view millimetres, the drive-shaft is lifting too, but after those 2-3 millimetres somenthing blocks.

i meanwhile even removed the core-plug from the block, to see inside...everything looks "normal"

i tried to turn the engine and in the same moment pulling on the dizzy....nothing.

any ideas?

the Dizzy´s alloy housing is broken into several pieces...at least the remainings are now unseized and can be rotated inside the engine´s block.

but: the dizzy still doos not come off the block. the alloy casing can be lifted a view millimetres, the drive-shaft is lifting too, but after those 2-3 millimetres somenthing blocks.

i meanwhile even removed the core-plug from the block, to see inside...everything looks "normal"

i tried to turn the engine and in the same moment pulling on the dizzy....nothing.

any ideas?

-

GinettaG15

- Guest contributor

- Posts: 79

- Joined: Sun Oct 16, 2022 7:12 pm

Re: some news from "my" Garage...Dolly 1850 related....

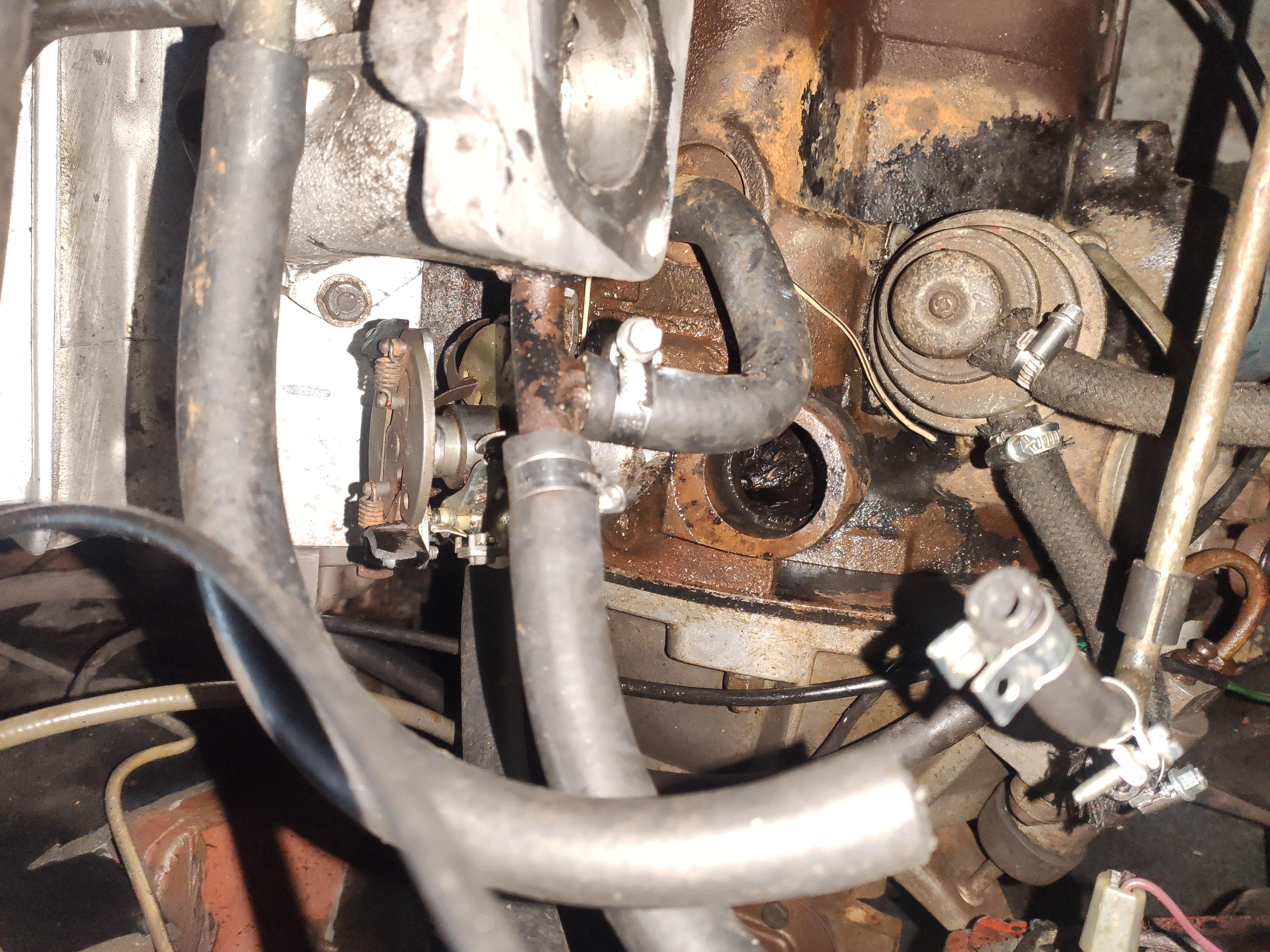

the result after another day in the garage is even more frustrating:

the distributor is now completely broken and the remaining aluminium casing is rock-silid inside the block.

tried with heat-gun and slide-hammer...up to know...no chance to free the remaining alloy:

the distributor is now completely broken and the remaining aluminium casing is rock-silid inside the block.

tried with heat-gun and slide-hammer...up to know...no chance to free the remaining alloy:

Re: some news from "my" Garage...Dolly 1850 related....

A bit drastic, but is it possible to remove the oil pump and then "tap" the hex oil pump drive shaft upwards to drive the distributor shaft/gear out which should drag the remaining alloy casting out? You will probably damage the drive shaft but that is easily replaced.

1975 Sprint Man O/D in Honeysuckle Yellow

1971 Stag Auto White

Too many cars, too little time!

1971 Stag Auto White

Too many cars, too little time!

-

cliftyhanger

- TDC Member

- Posts: 2539

- Joined: Sun Oct 26, 2008 7:26 am

Re: some news from "my" Garage...Dolly 1850 related....

I was going to suggest drilling the ali with progressively bigger drill bits, then a small chisel to crack the ali though and release the grip.

Use of grease/henry vacuum should stop stuff getting into the engine.

But I would have expected a slide hammer to have shifted it. Something is really stuck, possbly the O ring.

Use of grease/henry vacuum should stop stuff getting into the engine.

But I would have expected a slide hammer to have shifted it. Something is really stuck, possbly the O ring.

Clive Senior

Brighton

Brighton

-

GinettaG15

- Guest contributor

- Posts: 79

- Joined: Sun Oct 16, 2022 7:12 pm

Re: some news from "my" Garage...Dolly 1850 related....

i´m trying now to fabricate an adaptor which i will weld on top of the dizzy-shaft. this adaptor will have the same inner thread than my sliding-hammer....than i will warm again the block with a gas-flame and fingers crossed that i can pull the remaining-alloy out of the block via the pulling-force on the shaft....this said: i hope the split-pin, holding the drivegear, will resist the pulling-force.marshman wrote: ↑Fri Dec 30, 2022 12:26 pm A bit drastic, but is it possible to remove the oil pump and then "tap" the hex oil pump drive shaft upwards to drive the distributor shaft/gear out which should drag the remaining alloy casting out? You will probably damage the drive shaft but that is easily replaced.

and all this because i "just" wanted to adjust the ignition timng and later on convert the dizyy to electronic.

-

GinettaG15

- Guest contributor

- Posts: 79

- Joined: Sun Oct 16, 2022 7:12 pm

Re: some news from "my" Garage...Dolly 1850 related....

its done!!!

this afternoon i drilled 2 holes, 180 degrees opposite, into the remaining alloy-hub...i usded an drill of 8mm with ovesized length.

than i built an adaptor for my sliding hammer,welded it on the driveshaft and off it came with 5 strong pulls on the sliding-hammer.

this afternoon i drilled 2 holes, 180 degrees opposite, into the remaining alloy-hub...i usded an drill of 8mm with ovesized length.

than i built an adaptor for my sliding hammer,welded it on the driveshaft and off it came with 5 strong pulls on the sliding-hammer.

- xvivalve

- TDC West Mids Area Organiser

- Posts: 13579

- Joined: Thu Sep 28, 2006 1:13 pm

- Location: Over here...can't you see me?

Re: some news from "my" Garage...Dolly 1850 related....

That would have been my first suggestionmarshman wrote: ↑Fri Dec 30, 2022 12:26 pm A bit drastic, but is it possible to remove the oil pump and then "tap" the hex oil pump drive shaft upwards to drive the distributor shaft/gear out which should drag the remaining alloy casting out? You will probably damage the drive shaft but that is easily replaced.

-

GinettaG15

- Guest contributor

- Posts: 79

- Joined: Sun Oct 16, 2022 7:12 pm

Re: some news from "my" Garage...Dolly 1850 related....

too complicate....removing oilpan with engine insitu....my slidinghammer methode with adaptor worked perfectly.....xvivalve wrote: ↑Fri Dec 30, 2022 6:36 pmThat would have been my first suggestionmarshman wrote: ↑Fri Dec 30, 2022 12:26 pm A bit drastic, but is it possible to remove the oil pump and then "tap" the hex oil pump drive shaft upwards to drive the distributor shaft/gear out which should drag the remaining alloy casting out? You will probably damage the drive shaft but that is easily replaced.

the drastic way would have come into consideration as the really last attempt....