As some of you may have seen, unfortunately the engine in my newly acquired sprint recently expired with what looks like a spun bearing.

I havent had a chance to removed the old motor yet to properly diagnose what went wrong, but luckily Ive manage to pick up a sprint engine locally, and due to the history of it being unknown, Ive made a start to dismantle and check a few things (mains, big ends etc) rather than leave it to chance.

The good side, is that the engine is very good. The mains, big ends etc. all look as though it did very little mileage since a rebuild.

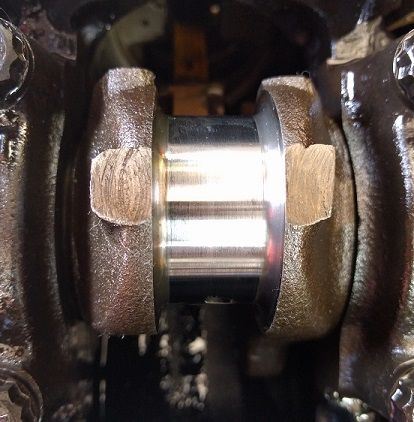

Mains (#2)

Crank (#2)

Big End (#2)

The issue I have picked up on today is the wear and the rounding off of the oil pump spindle:

Good end

Rounded end

Without a big leap of imagination, it wouldnt be extreme to assume that under certain conditions and a few more K's under the engine, that this rounding could become so bad as to no longer drive the oil pump or shear at high stress (or high RPM).

What are peoples opinions and has anyone come across this before?

Cheers

Andrew